Chiara’s slave

Well-Known Member

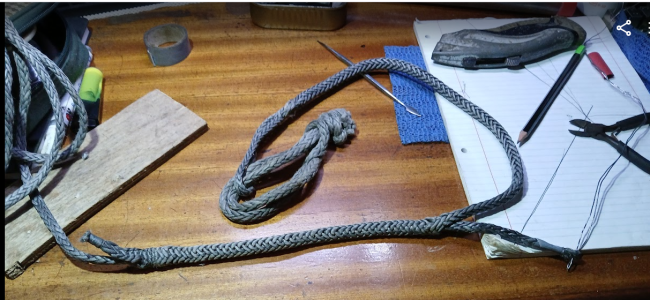

You could also consider tapering a dyneema line. If the splice has to take the load, then that is technically a better option. It’ll be fine on Will’s size boat of course, but a 38 ft racer, I think I’d rather taper if losing some diameter is necessary.