frocco

New member

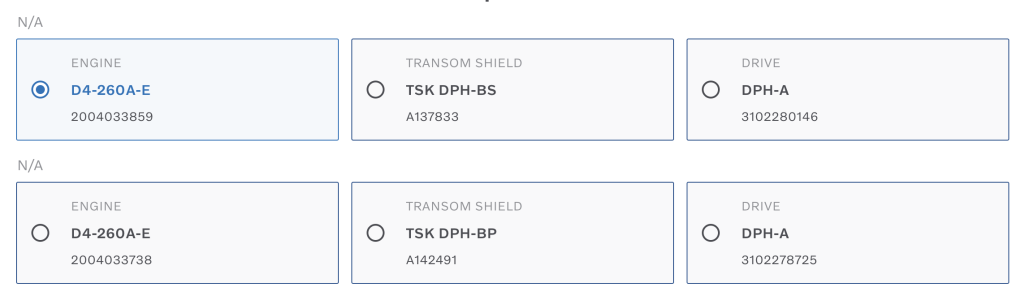

Hello, I have been struggling with a trim issue on my Formula 400 SS with twin D6 DPH. It has B transom assembly’s. When I trim all the way up, the port reads 40 deg the starboard reads 29 deg. That are both up

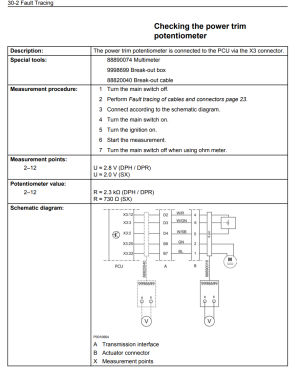

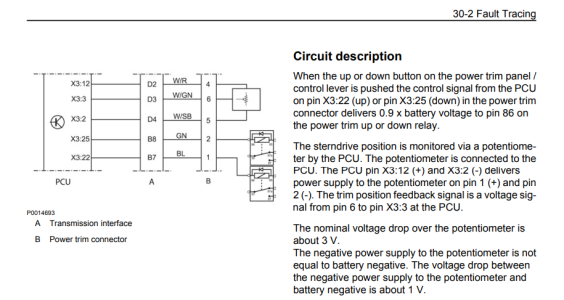

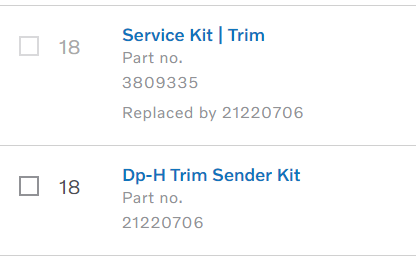

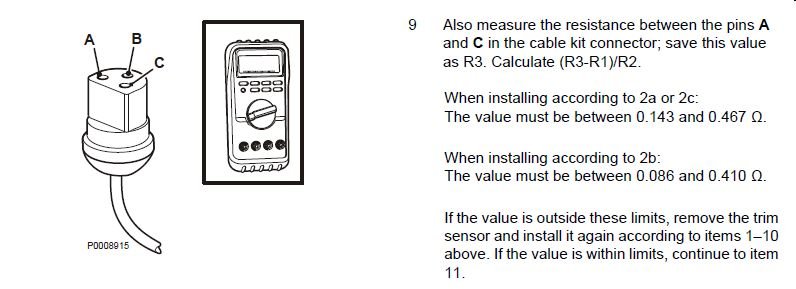

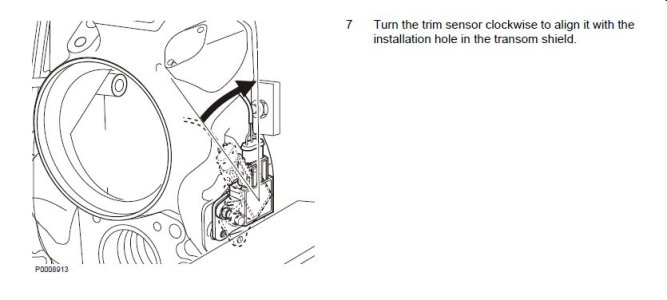

To their max tilt. When I calibrate max tilt stays at 40 and 29, all the way down reads -5 on both. As I trim up they do not stay in sync physically, the computer will lift them so they show equal on the guage but are physically at different positions. I don’t have a spare sensor to read with a meter to know what the typical full range resistance is from end to end. If you know the boat, I have no access to the senders without some tear down. If I decide to go after a sensor I would like to know which one is out of spec. Hoping that removing the cooler will give me some access. Any help or onsite would be much appreciated.

To their max tilt. When I calibrate max tilt stays at 40 and 29, all the way down reads -5 on both. As I trim up they do not stay in sync physically, the computer will lift them so they show equal on the guage but are physically at different positions. I don’t have a spare sensor to read with a meter to know what the typical full range resistance is from end to end. If you know the boat, I have no access to the senders without some tear down. If I decide to go after a sensor I would like to know which one is out of spec. Hoping that removing the cooler will give me some access. Any help or onsite would be much appreciated.