dunedin

Well-Known Member

With a LOT of trepidation I am considering biting the bullet and getting the saildrive seal replaced on our 2012 Volvo Penta D2-55F.

(Trepidation as I have herd of quite a few cases of seal problems AFTER changing, but none from people leaving seals unmolested for decades!)

There is ZERO chance of me doing this DIY, so will be an expensive job by the local VP dealer (circa £2k estimate earlier this year - made more tricky as seal is underneath a GRP hull fairing).

The Engine has now done circa 1,700 hours and generally been reliable. Been serviced regularly, but no extra work (other than new MDI's and s/s exhaust elbow).

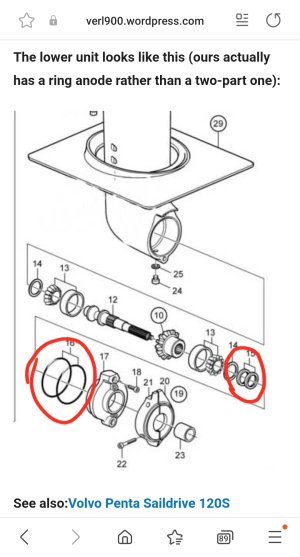

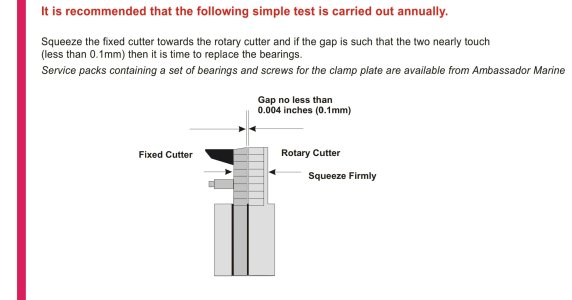

Nothing has been done to the saildrive except oil changes (generally done afloat by sucking out, which gets most but not all). The prop was briefly removed 8 years ago to fit an Ambassador Rope Stripper.

There is a very occasional very slight trace of oil in the under engine tray, perhaps coming from somewhere towards the rear of the engine (perhaps every 10 days or so of use I get enough to make a slight smear on a kitchen roll sheet). Oil consumption in 175 hours this season was less than 0,5 litre.

Whilst the boat is out of the water and the engine moved forward, is there anything worth getting the engineer to check / replace at the same time ?

Wondering about any difficult to access oil seals at back of engine, or saildrive seals (but again worry about messing with things which don't appear to be currently broken)

Should I replace the inlet seacock on the saildrive, although this seems entirely fine?

Thanks

(Trepidation as I have herd of quite a few cases of seal problems AFTER changing, but none from people leaving seals unmolested for decades!)

There is ZERO chance of me doing this DIY, so will be an expensive job by the local VP dealer (circa £2k estimate earlier this year - made more tricky as seal is underneath a GRP hull fairing).

The Engine has now done circa 1,700 hours and generally been reliable. Been serviced regularly, but no extra work (other than new MDI's and s/s exhaust elbow).

Nothing has been done to the saildrive except oil changes (generally done afloat by sucking out, which gets most but not all). The prop was briefly removed 8 years ago to fit an Ambassador Rope Stripper.

There is a very occasional very slight trace of oil in the under engine tray, perhaps coming from somewhere towards the rear of the engine (perhaps every 10 days or so of use I get enough to make a slight smear on a kitchen roll sheet). Oil consumption in 175 hours this season was less than 0,5 litre.

Whilst the boat is out of the water and the engine moved forward, is there anything worth getting the engineer to check / replace at the same time ?

Wondering about any difficult to access oil seals at back of engine, or saildrive seals (but again worry about messing with things which don't appear to be currently broken)

Should I replace the inlet seacock on the saildrive, although this seems entirely fine?

Thanks