You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

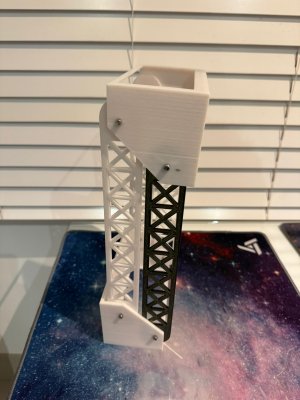

Does anybody know which Aux outboard bracket this is?

- Thread starter Hoist

- Start date

LittleSister

Well-Known Member

Looks like it might perhaps be custom made, rather than a branded item.

Refueler

Well-Known Member

I have to say its does look custom .. and home designed.

I would imagine its a bit of a handful to operate as well .... not only to pivot - but to remove / insert pins / bolts etc.

I would imagine its a bit of a handful to operate as well .... not only to pivot - but to remove / insert pins / bolts etc.

Dellquay13

Well-Known Member

It looks very PBO sketchbook to me. I would add a long drop nose pin across the cheeks of the outboard end to lock it in the upright position.

Last edited:

Bouba

Well-Known Member

I agree....that looks homemade.....but very clever.

Boathook

Well-Known Member

Looks like a bit of rope for that plus to lower and raise it.It looks very PBO sketchbook to me. I would add a long drop nose pin across the cheeks of the outboard end to lock it in the upright position.

I suspect that the design side took a bit of doing so that it cleared everything.

Hoist

Well-Known Member

Had the auxiliary over 10 years, but never fancied hanging it off the stainless steel rail.

The tohatsu has had less than 10 minutes running time and has been in the garage cause I don't believe it would be safe to put it there and try to transfer down at sea.

That bracket is really a perfect solution as the outboard can be stood up and almost stood on its skeg

It will also store the outboard lower which is better

The tohatsu has had less than 10 minutes running time and has been in the garage cause I don't believe it would be safe to put it there and try to transfer down at sea.

That bracket is really a perfect solution as the outboard can be stood up and almost stood on its skeg

It will also store the outboard lower which is better

Boathook

Well-Known Member

Paper and pencil to start the design followed by stiff board or cardboard and a more solid wood construction with the actual engine, etc.

Finally either alloy or stainless, diy or made by a fabricator.

Finally either alloy or stainless, diy or made by a fabricator.

rogerthebodger

Well-Known Member

My backup outboard is a 20 hp long shaft mounted on my Pushpit in a slotted frame that can be lifted and mounted in matching slots in my dive platform. The lifting can be done using my solar stern post and deck winch's

rogerthebodger

Well-Known Member

If I had been designing the bracket post by the OP, I would have made it as a Pantagraph so it can be lowered with the engine retaining its proper orientation when lowered

Boathook

Well-Known Member

I assume looking the picture posted by the OP that when the outboard is lowered down into position, that it will be vertical ready to use. The 'support legs' are fixed at different centres.If I had been designing the bracket post by the OP, I would have made it as a Pantagraph so it can be lowered with the engine retaining its proper orientation when lowered

Bouba

Well-Known Member

It is pantagraphed....the uprights are actually two separate tubes of the same length but offset and are individually on pivotsIf I had been designing the bracket post by the OP, I would have made it as a Pantagraph so it can be lowered with the engine retaining its proper orientation when lowered

rogerthebodger

Well-Known Member

It is pantagraphed....the uprights are actually two separate tubes of the same length but offset and are individually on pivots

It looks like the pivit points are not in the correct position for a Pantagraph to function correctly as the lengths of the Pantagraph need to be the same length to maintain the correct angle for the outboard bracket

A picture showing it in the lowered position would clarify the operation.

Boathook

Well-Known Member

It would be nice to see a picture of it in the lowered position but to me the pivot points look correct in that the aft upright becomes the lower 'upright' and the bracket that the engine is bolted to swings to the correct position.It looks like the pivit points are not in the correct position for a Pantagraph to function correctly as the lengths of the Pantagraph need to be the same length to maintain the correct angle for the outboard bracket

A picture showing it in the lowered position would clarify the operation.

I'm not sure whether the design is a pentagraph but maybe a parallelogram. Either way it is an ingenious design for a problem.

Sandro

Well-Known Member

As far as one can rather clearly see from the photo, the opposite sides of the hinged quadrilateral are the same length. It is a parallelogram. When released and pushed astern and then down the motor will do all the travel perfectly vertical and so it will remain when complelely lowered in working position.

A very clever solution, simple, strong and always ready.

Only ,but unavoidable, common issues are the difficult reaching of the far outboard commands and the propeller spinning in the air in waves.

A very clever solution, simple, strong and always ready.

Only ,but unavoidable, common issues are the difficult reaching of the far outboard commands and the propeller spinning in the air in waves.

Last edited:

greeny

Well-Known Member

Just in the process of fabricating bracket for auxiliary outboard on my RIB. This design has made me stop and re evaluate my original design. Looks to have a lot of merit over a "fixed" bracket for me. Just need to get measurements from the RIB to see if it's possible. PBO at it's best. Sharing of knowledge and solutions is probably better here than any other forum I've been on.

Hoist

Well-Known Member

Greeny it’s had the same effect for me.

The bracket was shown to me by someone with the same rib as us.

As previously suggested I am going to mock up a bracket in wood and if all goes well take it to the local fab shop.

Now that the boat is 20 years old it’s time we carried an aux outboard.

The bracket was shown to me by someone with the same rib as us.

As previously suggested I am going to mock up a bracket in wood and if all goes well take it to the local fab shop.

Now that the boat is 20 years old it’s time we carried an aux outboard.

Bouba

Well-Known Member

It appears to have a stop pin in the base to keep it upright....as well as a rope to secure it and probably lower it

Bouba

Well-Known Member

And they should be called ‘Boy Jacks’....in a tribute to the boat in the photo

Hoist

Well-Known Member

Other threads that may be of interest

- Replies

- 15

- Views

- 607

- Replies

- 24

- Views

- 455

- Replies

- 5

- Views

- 325