B27

Well-Known Member

Mine seem to be some slightly stretchy line, I don't see any need to adjust them.

Every boat's differentMine seem to be some slightly stretchy line, I don't see any need to adjust them.

Which probably is not far from the 70% suggested by Tranona, ages ago, in #6Ours worked fine set at the top cross trees out of two.

In our case closer to 75% but I'm not nit picking.Which probably is not far from the 70% suggested by Tranona, ages ago, in #6

Glad to hear that you do not have nitsIn our case closer to 75% but I'm not nit picking.

Same as us then. And yes, Mrs C just watches the leech as she steers, and issues the command to hoist at the right time. Once the leech is through the lazyjacks, she can start to bear off onto the desired track.Mine are at the spreaders on a fractional rig boat, so less than 50% up the luff.

We have a stack pack.

The only thought I need to give to them is to take care the battens don't catch during hoisting.

Maybe lower is better from this POV, because during a hoist, the batten ends are outside the lazyjacks sooner?

So long as you look at the sail while hoisting, it's a non-problem, you just hoist when things aren't going to catch.

Sail is on luff slides.

A bolt rope luff might be a different animal?

I stand astride the tiller and hoist while watching the sail and steering at the same time. When the sail passes the lazy jacks I free the mainsheet and continue as far as I can. With luck my crew will then winch up the last few inches and tension it. It is actually a bit easier with some wind, which makes the sail flap and work its way heavenwards.Same as us then. And yes, Mrs C just watches the leech as she steers, and issues the command to hoist at the right time. Once the leech is through the lazyjacks, she can start to bear off onto the desired track.

Our sail, as you might imagine, is heavy for a 30 footer. Battens, cars, much heavier cloth than you’d find on a 30 foot mono. The main halyard is 2:1, which makes hoisting slightly less strain, but on the other hand there’s about 25 metres of rope to haul. I’d have to stick the autopilot on if I was alone. An aside, for the topic though. What I’ve got from the thread is that the position of your lazyjacks on the mast is unimportant. What works for you is good.I stand astride the tiller and hoist while watching the sail and steering at the same time. When the sail passes the lazy jacks I free the mainsheet and continue as far as I can. With luck my crew will then winch up the last few inches and tension it. It is actually a bit easier with some wind, which makes the sail flap and work its way heavenwards.

In our case closer to 75% but I'm not nit picking.

Glad to hear that you do not have nits

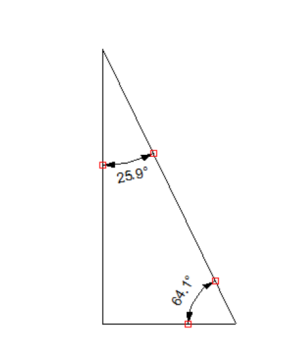

Will depend on how far down the boom the fixing points are in relation to the height of the fixings on the mast as well, just zapped mine with a laser, any lower the outside tab sewn onto the bag would be putting all the stress on one corner of the stitching.What I’ve got from the thread is that the position of your lazyjacks on the mast is unimportant. What works for you is good.

However, if ypur bag is made for a lower fixing, and different angle, all is well. The lines go through loops on our bag without strain. They’re fixed on the boom as well.Will depend on how far down the boom the fixing points are in relation to the height of the fixings on the mast as well, just zapped mine with a laser, any lower the outside tab sewn onto the bag would be putting all the stress on one corner of the stitching.

View attachment 179470

They measured, they made. No discussion of fixing height on the mast when I got mine made. It works just great, another game changer single handed . Any lower it wouldn't sit right, too much lateral load & not enough vertical.However, if ypur bag is made for a lower fixing, and different angle, all is well. The lines go through loops on our bag without strain. They’re fixed on the boom as well.

It fits, it works for you. Our system is built around the lower attachment. That fits, and works for us. The key is obviously to have everything designed to work together. If we suddenly decided to attach ours to the next diamond up, it would tear the tapes off the bag. Just like the reverse would do to yours.They measured, they made. No discussion of fixing height on the mast when I got mine made. It works just great, another game changer single handed . Any lower it wouldn't sit right, too much lateral load & not enough vertical.

what are the angles on yours? Might be similar. Your attachment tabs must be an odd shape for the resultant force to be outside the base if the force angle goes higher.It fits, it works for you. Our system is built around the lower attachment. That fits, and works for us. The key is obviously to have everything designed to work together. If we suddenly decided to attach ours to the next diamond up, it would tear the tapes off the bag. Just like the reverse would do to yours.

Not sure it needs to be that technical.It fits, it works for you. Our system is built around the lower attachment. That fits, and works for us. The key is obviously to have everything designed to work together. If we suddenly decided to attach ours to the next diamond up, it would tear the tapes off the bag. Just like the reverse would do to yours.

I’ve not paid it that much attention before, TBH. It’s one thing on the boat we have not changed apart from having a new bag made, identical to the old one. A side on photo would show what goes on, but it’s not the kind of photo you take, unless you’ve got problems. But our rearmost line runs in a straight line from the boom attachment, via a webbing loop on the bag, to the 1st block. The bag therefore just hangs there waiting to receive the sail. It’s not rocket science, just some obvious geometry.Not sure it needs to be that technical.

It's two panels of canvas hanging from three strings each, via some mediocre line.

You make it sound like Nora Batty's underwear.

Why is it heavy? I would have thought that for a tri it would be light weight. That is, after all, part of its performance advantage off the wind. My fully battened fibrecon mainsail on 31 ft mono is 8oz cloth & that should be plenty for a 30ft lightweight boat. My last dacron sail was 7ozOur sail, as you might imagine, is heavy for a 30 footer. Battens, cars, much heavier cloth than you’d find on a 30 foot mono. The main halyard is 2:1, which makes hoisting slightly less strain, but on the other hand there’s about 25 metres of rope to haul.