skyflyer

Active member

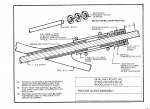

My boat has this type of shaft seal. 3 rings of square section braided ptfe “cord” get squeezed by a large nut and thus form a seal against the prop shaft (I believe the exact same system is used in garden taps!).

in order to prevent friction and heat build up, the pressure on the nut is adjusted to allow a small ingress of water, 4 or 5 drips per minute whilst shaft is turning. This reduces to about 1 per minute (or less) when engine is stopped.

My question: is this an unusual arrangement In the UK? (It’s a US built boat) My prospective purchasers surveyor had never seen such a system without some other form of lubrication?

in order to prevent friction and heat build up, the pressure on the nut is adjusted to allow a small ingress of water, 4 or 5 drips per minute whilst shaft is turning. This reduces to about 1 per minute (or less) when engine is stopped.

My question: is this an unusual arrangement In the UK? (It’s a US built boat) My prospective purchasers surveyor had never seen such a system without some other form of lubrication?