jamie N

Well-Known Member

Of course, it could be any diesel heater, but the issue that I had was where the exhaust pipe does become extremely hot during operation, it's wise to insulate it in order to prevent damage to perhaps the hull, or gear in the locker that it maybe passes through, whatever.

I used a fairly standard exhaust wrap, one of dozens available, and duly wrapped the pipe, paying particular attention to where it passes through a bulkhead, and up through the stern locker to the actual exhaust fitting on the transom. The heater unit is in the engine bay of my GK24, where there's actually no engine, as I'm an outboard variant. This bay is accessed from the cabin, which is where the fresh air to be heated is also positioned, because the alternative's not feasible.

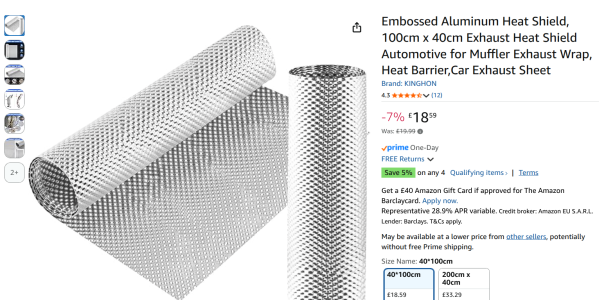

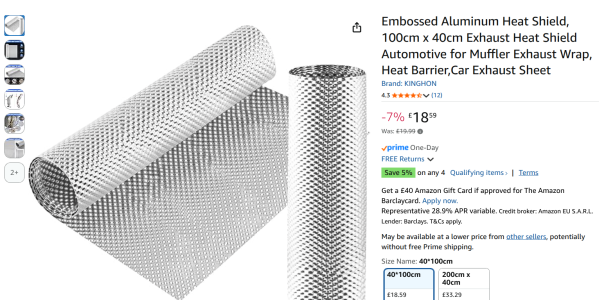

Anyway, it is mentioned that the wrap stuff will seem to smoke a bit as the chemicals burn off, it's also known that they do attract condensation and will steam as they dry out when the heater's on, so I persevered with it for about 30 hours running, and still had a 'smoky' cabin, which is the problem. The smoke is largely steam, but also still the stuff from the wrap. I do have a gas/particulate meter, and it reads as everything being OK, but it's not right, so I changed the wrap out for straightforward aluminium wrap, which seems to be a far better solution for me, albeit after only an hour of running. If I'm the only one who's suffered this, oh well, but it might help others.

I used a fairly standard exhaust wrap, one of dozens available, and duly wrapped the pipe, paying particular attention to where it passes through a bulkhead, and up through the stern locker to the actual exhaust fitting on the transom. The heater unit is in the engine bay of my GK24, where there's actually no engine, as I'm an outboard variant. This bay is accessed from the cabin, which is where the fresh air to be heated is also positioned, because the alternative's not feasible.

Anyway, it is mentioned that the wrap stuff will seem to smoke a bit as the chemicals burn off, it's also known that they do attract condensation and will steam as they dry out when the heater's on, so I persevered with it for about 30 hours running, and still had a 'smoky' cabin, which is the problem. The smoke is largely steam, but also still the stuff from the wrap. I do have a gas/particulate meter, and it reads as everything being OK, but it's not right, so I changed the wrap out for straightforward aluminium wrap, which seems to be a far better solution for me, albeit after only an hour of running. If I'm the only one who's suffered this, oh well, but it might help others.