steve yates

Well-Known Member

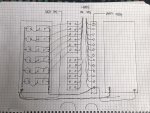

Sorry to keep asking questions about this, I'm almost there but I want to be very clear in my mind what I'm about before I actually do it. My lastpost on electrics was whether I needed busbars or not with my set up of switch panels, it convinced me I want them to keep the wiring secure and tidy, especially when the fuse box lid is opened. As you can see from the pic,there are 2 panels in the lid of my fusebox, with 6 switches each. Thats handy as it gives me a individual switch for every single load.

I think I want a positve bus bar and a negative busbar, mounted in the back or base of the box. (pic of the attachments at back of switch panels attached)

Q1) Will two of these do the trick? 100Amp BusBar 2 M6 Studs 12 M4 Screws Terminals with Cover Kit Bus Bars Ground Distribution Blocks: Amazon.co.uk: Sports & Outdoors

Or are smaller ones and just attach a couple of wires to each screw, but if so would I lose both devices if a fuse blows on one switch? I don't think I do , but want to be sure.

I understand that I basically bring the wires from all my various devices into the box, and run the pos wire for each one to a separate screw in the pos busbar, and run the neg wire of each device to the corresponding screw on the neg bus bar. Then I take a short length from each pos screw to the pos connection at the relevant fuse in the panel, and repeat the same with a short length from each neg busbar screw to the neg connection at the relevant switch in the panel.( Currently there is a short length of pigtail on these neg connections which I just remove and chuck.)

My pos battery cable will come into the box and attach to a stud on the pos bus bar, a neg battery cable will run from a stud on the neg bus bar back to the battery.

What I don't have clear is exactly how the busbars and the switch panels are connected.

So Q2) is, should I run two lengths of pos battery cable from the other stud on the pos busbar, one to each switch panel? And then the same with 2 lengths of neg battery cable attached to the other stud on the neg busbar, with one cable to the neg connection on each switch panel?

This is how I think it should go, but someone mentioned dasiychaining the two switch panels together, is that an alternative method and how exactly would I do that, if my idea above is incorrect?

Or in fact, as long as there is a cable from batt to pos busbar and another from neg busbar back to batt, will that suffice as all the individual device wires between the busbars and switch panels will make the circuit as they are switched on? This is actually where I have been confusing myself I think.

And lastly, q3) I say battery cable between the busbars and switch panel, but if I do need a large capacity cable between switch panel and busbar, does it have to be? The busbars are rated at 100a, can I use slimmer cable between busbars and switch panels as long as it is rated above the total current likely from all 6 switches at once? Thinking of bulkiness and space in the box when closed.

Thanks

I think I want a positve bus bar and a negative busbar, mounted in the back or base of the box. (pic of the attachments at back of switch panels attached)

Q1) Will two of these do the trick? 100Amp BusBar 2 M6 Studs 12 M4 Screws Terminals with Cover Kit Bus Bars Ground Distribution Blocks: Amazon.co.uk: Sports & Outdoors

Or are smaller ones and just attach a couple of wires to each screw, but if so would I lose both devices if a fuse blows on one switch? I don't think I do , but want to be sure.

I understand that I basically bring the wires from all my various devices into the box, and run the pos wire for each one to a separate screw in the pos busbar, and run the neg wire of each device to the corresponding screw on the neg bus bar. Then I take a short length from each pos screw to the pos connection at the relevant fuse in the panel, and repeat the same with a short length from each neg busbar screw to the neg connection at the relevant switch in the panel.( Currently there is a short length of pigtail on these neg connections which I just remove and chuck.)

My pos battery cable will come into the box and attach to a stud on the pos bus bar, a neg battery cable will run from a stud on the neg bus bar back to the battery.

What I don't have clear is exactly how the busbars and the switch panels are connected.

So Q2) is, should I run two lengths of pos battery cable from the other stud on the pos busbar, one to each switch panel? And then the same with 2 lengths of neg battery cable attached to the other stud on the neg busbar, with one cable to the neg connection on each switch panel?

This is how I think it should go, but someone mentioned dasiychaining the two switch panels together, is that an alternative method and how exactly would I do that, if my idea above is incorrect?

Or in fact, as long as there is a cable from batt to pos busbar and another from neg busbar back to batt, will that suffice as all the individual device wires between the busbars and switch panels will make the circuit as they are switched on? This is actually where I have been confusing myself I think.

And lastly, q3) I say battery cable between the busbars and switch panel, but if I do need a large capacity cable between switch panel and busbar, does it have to be? The busbars are rated at 100a, can I use slimmer cable between busbars and switch panels as long as it is rated above the total current likely from all 6 switches at once? Thinking of bulkiness and space in the box when closed.

Thanks

Attachments

Last edited: