McFrancis

New Member

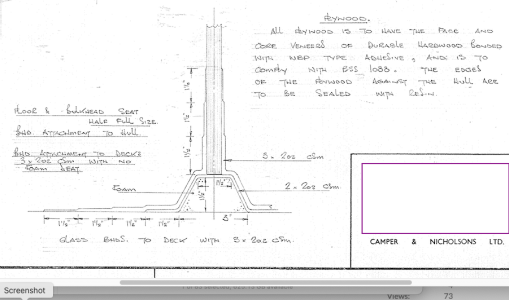

I've got a rotten piece of bulkhead caused by a long term leak that has now been repaired.

I've cut out the offending piece and the fibreglass tabs joining it to the hull. The boat is a Westerly Seahawk.

I'm in a quandary, I've seen conflicting advice, some say that the bulkhead should be hard against the hull, others that it should sit on a bed of silaflex, to avoid hard spots.

I've made the replace piece of bulkhead tight to the hull, but not fitted it yet. It would be easy to take a couple of millimeters off the hull side of the new piece of bulkhead if bedding is the way to go.

Any advice welcome. Should it be tight or bedded in?

I've cut out the offending piece and the fibreglass tabs joining it to the hull. The boat is a Westerly Seahawk.

I'm in a quandary, I've seen conflicting advice, some say that the bulkhead should be hard against the hull, others that it should sit on a bed of silaflex, to avoid hard spots.

I've made the replace piece of bulkhead tight to the hull, but not fitted it yet. It would be easy to take a couple of millimeters off the hull side of the new piece of bulkhead if bedding is the way to go.

Any advice welcome. Should it be tight or bedded in?