burgundyben

Well-Known Member

Be careful. The rudder is extraordinarily heavy, much more so than you realise (ex Westerley Sea School maintenance bod thats had a lot of rudders out of Westerly boats)

I would drill a hole in the bottom of the rudder from underneath the tip, if you haven't done so already to drain what looks like a wet bottom half. I used a 5mm drill, with a hole at the top to let air in and a hole at the bottom to let water out.

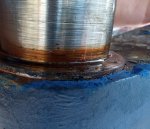

Might just be the way the photo takenIn the last photograph the diameter of the shaft appears to be less at the base than the rest - clear air between the upper and lower gap above the bearing/washer, or is this an outer sleeve on the shaft?

Could this be a sign that the shaft assembly has moved within the rudder blade, a small amount vertically. Just seems odd. I would expect the diameter of the post to to be the same as the bearing, but maybe not in this design. Bearing. renewal would not be possible would it?

Great plan.I'm going to grind it back and repair for now. Since no more water is coming out for a few days. In the late spring/early summer when she comes out for hull work and she's already up on the crane I'll pull the rudder completely, split it open, dry completely (in better weather than now!), and check inside for any supporting work that may need to be done. And I have someone in the marina who is experienced with this kind of repair and can help advising. 'Consulting' fees will be paid in barbecues and beer ;-)

For now I wonder how many layers of fiberglass will seal it well until then? I got a two inch wide roll. So I'm thinking one strip down along the crack, and three strips horizontally to wrap around the sides. Then a few pieces with half circles cut in place on either side of the flange, to seal up to the metal. maybe do that two deep. Then primocon/antifoul.

Good enough for one winter?

....don't launch this year get the boat right you will enjoy the work and learning process and be happier and more confident for it.

This is unquestionably an extreme response to a common observation on rudders. Many are by their construction damp or even wet internally. Loose talk about tangs rotting and rudders decomposing does no service to concerned owners. Splitting the rudder to examine it and reseal is without sound purpose, even if done professionally. Draining water from the blade by drilling low down and resealing has some value. Resealing at the junction between blade and post has value and is undoubtedly the issue here. Laying up for a season to rebuild etc is entirely OTT. Many other pieces of boat equipment have a higher failure rate than rudders....I'm going to grind it back and repair for now. Since no more water is coming out for a few days. In the late spring/early summer when she comes out for hull work and she's already up on the crane I'll pull the rudder completely, split it open, dry completely (in better weather than now!), and check inside for any supporting work that may need to be done. And I have someone in the marina who is experienced with this kind of repair and can help advising. 'Consulting' fees will be paid in barbecues and beer ;-)

For now I wonder how many layers of fiberglass will seal it well until then? I got a two inch wide roll. So I'm thinking one strip down along the crack, and three strips horizontally to wrap around the sides. Then a few pieces with half circles cut in place on either side of the flange, to seal up to the metal. maybe do that two deep. Then primocon/antifoul.

Good enough for one winter?

I have rebuilt two failed ruddersThis is unquestionably an extreme response to a common observation on rudders. Many are by their construction damp or even wet internally. Loose talk about tangs rotting and rudders decomposing does no service to concerned owners. Splitting the rudder to examine it and reseal is without sound purpose, even if done professionally. Draining water from the blade by drilling low down and resealing has some value. Resealing at the junction between blade and post has value and is undoubtedly the issue here. Laying up for a season to rebuild etc is entirely OTT. Many other pieces of boat equipment have a higher failure rate than rudders....

Just a thought if you decide to split the rudder. I went through this last winter taking the rudder home. It just about stood upright in the downstairs bathroom. The transom hung rudder suffered a large gouge . From where I don't know.I'm going to grind it back and repair for now. Since no more water is coming out for a few days. In the late spring/early summer when she comes out for hull work and she's already up on the crane I'll pull the rudder completely, split it open, dry completely (in better weather than now!), and check inside for any supporting work that may need to be done. And I have someone in the marina who is experienced with this kind of repair and can help advising. 'Consulting' fees will be paid in barbecues and beer ;-)

For now I wonder how many layers of fiberglass will seal it well until then? I got a two inch wide roll. So I'm thinking one strip down along the crack, and three strips horizontally to wrap around the sides. Then a few pieces with half circles cut in place on either side of the flange, to seal up to the metal. maybe do that two deep. Then primocon/antifoul.

Good enough for one winter?

That is exactly right ( imo!?)Just a thought if you decide to split the rudder. I went through this last winter taking the rudder home. It just about stood upright in the downstairs bathroom. The transom hung rudder suffered a large gouge . From where I don't know.

I watched a number of Youtube videos on opening up the rudder. I decided to cut a rectangular "window" in one side rather than split at the join. I found this a lot easier with my limited skills and good access to inspect the interior. The foam was easy to remove where necessary. I epoxied the window back, dug out a bit on the rudder's join and applied epoxy filler where necessary. It can make a difference which side to open up . If you can find out which side of the rudder has the most interior metal.

Pearson ( ‘merican) favoured aluminium for rudder stocks on some early models . My neighbour dove the intracoastal waterway to recover his , which snapped at the top of the blade. I removed mine, sold it (!) and made a new one using stainless heavy wall tube with three flat bars slotted through and spot welded and then wrapped in high density foam and grp sheathing , faired .I would drill a couple of holes higher up the rudder. The foam filling may actually seal the rudder mid height & there may be water trapped in the upper half. That was the case in my rudder. I drilled 3-4 holes at 4 inch centres from the top down untill the water stopped coming out. As you have to fill holes lower down it will be easy to fill a couple more while you have the epoxy mixed.

This is a picture of my 11 year old rudder after it broke. I know that you have a stainless steel stock & mine is aluminium but you might note the missing foam & the massive corrosion in the stock 12 inches down from the top of the rudder inside. Presumably stainless steel is open to the same issues. Albeit hopefully to a limited extent. Hopefully yours has a better filling of foam

View attachment 143187

In the last photograph the diameter of the shaft appears to be less at the base than the rest - clear air between the upper and lower gap above the bearing/washer, or is this an outer sleeve on the shaft?

Could this be a sign that the shaft assembly has moved within the rudder blade, a small amount vertically. Just seems odd. I would expect the diameter of the post to to be the same as the bearing, but maybe not in this design. Bearing. renewal would not be possible would it?

I would drill a couple of holes higher up the rudder. The foam filling may actually seal the rudder mid height & there may be water trapped in the upper half. That was the case in my rudder. I drilled 3-4 holes at 4 inch centres from the top down untill the water stopped coming out. As you have to fill holes lower down it will be easy to fill a couple more while you have the epoxy mixed.

This is a picture of my 11 year old rudder after it broke. I know that you have a stainless steel stock & mine is aluminium but you might note the missing foam & the massive corrosion in the stock 12 inches down from the top of the rudder inside. Presumably stainless steel is open to the same issues. Albeit hopefully to a limited extent. Hopefully yours has a better filling of foam

View attachment 143187

Pearson ( ‘merican) favoured aluminium for rudder stocks on some early models . My neighbour dove the intracoastal waterway to recover his , which snapped at the top of the blade. I removed mine, sold it (!) and made a new one using stainless heavy wall tube with three flat bars slotted through and spot welded and then wrapped in high density foam and grp sheathing , faired .

I would like to say that by tweaking the shape slightly to a NASAsection I achieved one degree less between tacks but it was also not quite so nice on the feedback through the tiller . But , it was STRONG?