alexincornwall

Well-Known Member

Hi all,

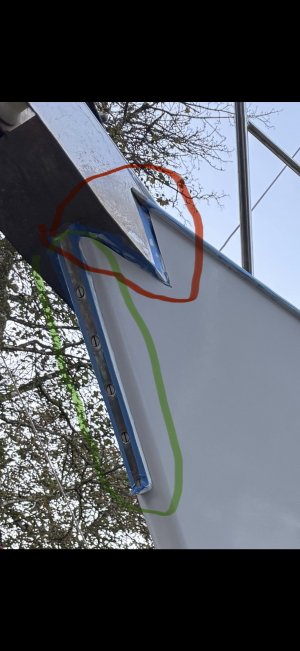

We'll shortly be relaunching following a long winter of maintenance including having our topsides repainted. The contractor that carried out our the paintwork is in the process of demasking and completing any final odd jobs, to include reapplying silicone around the forestay chain plate (marked green in this old photo, the best I have to hand). He indicated that there was no silicone present where the bow roller meets the hull/bulwarks (circled red). From memory, I think he is right as I recall thinking it odd. Is there any reason why the vertical and horizontal gaps wouldn’t have been sealed?

I’m inclined to ask him to go ahead and get a decent bead of mastic in there. I also think it would make good sense to apply a thin bead running the length of the boat where the toe rail meets the bulwark on the outside edge. I'm not a huge fan of silicone but given the nature of the job, this seems an appropriate product as no adhesion is required and it obviously needs to dry.

Does anyone have any thoughts on this please? I'm now wondering if the bow was deliberately fitted unsealed to allow and water ingress to run off/dry out.

Many thanks

We'll shortly be relaunching following a long winter of maintenance including having our topsides repainted. The contractor that carried out our the paintwork is in the process of demasking and completing any final odd jobs, to include reapplying silicone around the forestay chain plate (marked green in this old photo, the best I have to hand). He indicated that there was no silicone present where the bow roller meets the hull/bulwarks (circled red). From memory, I think he is right as I recall thinking it odd. Is there any reason why the vertical and horizontal gaps wouldn’t have been sealed?

I’m inclined to ask him to go ahead and get a decent bead of mastic in there. I also think it would make good sense to apply a thin bead running the length of the boat where the toe rail meets the bulwark on the outside edge. I'm not a huge fan of silicone but given the nature of the job, this seems an appropriate product as no adhesion is required and it obviously needs to dry.

Does anyone have any thoughts on this please? I'm now wondering if the bow was deliberately fitted unsealed to allow and water ingress to run off/dry out.

Many thanks