AlexL

Well-Known Member

I've got a First 21.7, planning to replace all the standing and running rigging this winter.

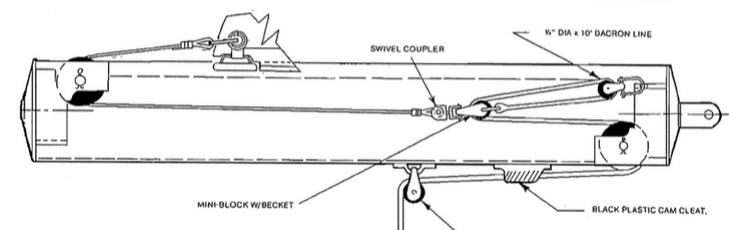

The boom is currently in my garage, and i'm measuring up all the lines to replace. Reef lines go from one end to the other, simple - i'll just pull a mouse line through. The outhaul on the other hand appears to have 3 ends so I'm assuming there's a shuttle block in the boom which makes it difficult. I could leave the line tied to the block (not sure which 'end' that is, but I'm sure I could shine a torch and see) and then just mouse line and replace the other bit, but I'd like to replace it all if poss.

Any ideas? the only thing I can see is to drill out the rivets for one of the end fittings and then re-rivet later - any risks / gotchas with this?

The boom is currently in my garage, and i'm measuring up all the lines to replace. Reef lines go from one end to the other, simple - i'll just pull a mouse line through. The outhaul on the other hand appears to have 3 ends so I'm assuming there's a shuttle block in the boom which makes it difficult. I could leave the line tied to the block (not sure which 'end' that is, but I'm sure I could shine a torch and see) and then just mouse line and replace the other bit, but I'd like to replace it all if poss.

Any ideas? the only thing I can see is to drill out the rivets for one of the end fittings and then re-rivet later - any risks / gotchas with this?