Fishtigua

Active member

But according to some anodes producers, alu is as good as zinc also in salt water.

Just as an aside, has anyone checked with the likes of Volvo, CAT or MTU which they prefer in their engines?

But according to some anodes producers, alu is as good as zinc also in salt water.

Hi

Pretty definitively;

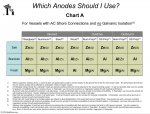

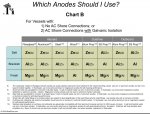

Zinc are for sea water

Magnesium are for fresh water

Aluminium are for brackish or a mix of both and are also what the OEM will play it safe with, as in with merc and VP outdrives. They will not offer the same protection as a zinc in SW, for certain.

Tecnoseal anodes (zinc version) is what I used last season, and they worked brilliantly. I suppose the version you are referring to is the alu ones, whose part numbers in their catalogue ends with "AL" (as opposed to no letters for zinc, and "MG" for magnesium).

I'm not sure if Tecnoseal managed to get any patent on their own alu alloy, but pretty sure they are not alone in offering alu anodes.

"Alu" always meaning a special alloy of course, obviously different from any structural alu parts used in outdrives or whatever.

Anyway, fwiw, material aside, here in IT Tecnoseal stuff is considered the best, and I don't think you will get wrong with that.

I will be interested to hear about your experience!

Does anyone know if the crud layer on a zinc affects the efficacy?

Does anyone know if the crud layer on a zinc affects the efficacy?

Island if Ireland has a distinct northern part belonging to the U.K. or just Ireland ?

Nomenclature guys

Aluminium or an Alloy as said in post above ?

I don,t think there’s such a thing as an Aluminium anode , that’s an anode made of Aluminium with zero deliberate additives .

View attachment 75754

Aluminium is LESS noble than 99.9% Zinc and thus its proctective currernt is lower .

However making an alloy with other metals may give a marginal slight increased voltage , but above a certain V if you go too high you may end up protecting your neighbors boat(s) anyhow .

Zinc is the go to for seawater on a shaft drive more so if that seawater is more salty - Er like the Med .

Zinc with [ insert your metal % ] will deplete less and last longer .

Your aluminium ALLOYs like the one NB quote s have zinc in a smaller concentrations hance the longevity.

The base bulk substance of AL gives off a lower current, it’s its additives use of other metals inc some zinc that slightly inc the V .

Protection Vs depletion

If it ain’t depleting it’s not working !

You want it the anode to deplete not your sterngear corrode - right ?

With a Med based boat the depletion rate is easy to manage with 99.9 % Zinc , you can easily either snorkel or better with a bottle dive .

I’ve replaced prop anodes in Oct and happpy to do so to make sure it’s ok sitting in the marina over the closed season .

I replace when 1/2 worn not necessary at the annual lift .

Just want what’s best in terms of protection.

Caking your hull with copper coat is huge source of potential problems that could upset a nice protective equilibrium ( 99.9%zinc or an alloy mostly of AL ) not be ignored.An unnecessary layer ( scuse the pun ) of complications .

You have the added worry of balancing the electrochemical effects of your copper coat with your anodic protection. Good luck with that .As said before I fail to understand how in one breath the copper is wrapped up in resin thus rendered inert and in the other it’s constantly exposed to give antifoul properties? Huh !

Caking your hull with copper coat is huge source of potential problems that could upset a nice protective equilibrium ( 99.9%zinc or an alloy mostly of AL ) not be ignored.An unnecessary layer ( scuse the pun ) of complications.

That's unlikely to be ever included in my "to dos" list, PF...You need to get a quantitative measurement of the surface or other bits of the stern gear.

I can’t figure it out the exact affect ( agreed if any ? ) of CC ,on anodic protection .

I,am righty’s or wrongly coming from the other direction .I don't think the CopperCoat will make any difference because the flakes of copper are not connected to each other or to the bonding system.

The copper is encapsulated in resin and must be exposed to work but I believe (& I'm happy to be told I'm wrong) that each piece of copper is insulated from the next by the resin; so no circuit is made.

i.e if you take a CopperCoated hull and stick a meter across two exposed pieces of copper you should see open circuit.