whiteoaks7

New member

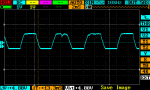

Does anyone know what comes squirting out of the W terminal (the one connected to the rev counter)? Is it a pulse train or voltage proportional to the rpm? Also, is the standard rev counter a voltmeter or something more complex? I want to measure rpm with a PIC (fun winter project).

Any answers to any questions gratefully received.

Any answers to any questions gratefully received.