Stonemonkey

New Member

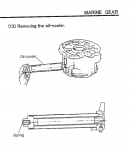

It froze over the winter. Cooling water floods into the gear box. I took the box out and open the cooler, looked inside, I don't see cracks on the walls, I assume something is bad at the far end. I'd like to take out the cooler body without damaging it. The manual is short on describing how. Any ideas?

Attachments

Last edited: