differentroads

Well-Known Member

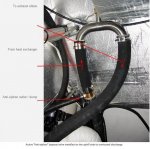

Can anyone help me with the dimensions of the Yanmar riser exhaust mixing elbow. I need the total height above the exhaust outlet on the engine, the height of the mixing point above the engine outlet and how far it projects forward of the engine, please. I'm checking that a different type of mixing elbow will fit in my engine space before I buy this type https://www.parts4engines.com/yanmar-3gm30-stainless-exhaust-outlet/ I have a 3GM30 but the same riser looks like it is used on many other models, just with different engine mounts

I want to replace my current downward facing mixing elbow with a u shaped riser as the top of my engine is level with the waterline. so the current mixing point is below it. It's also the same height as the top of the current waterlock. Pretty poor design, I gather, and probably the reason why I've had seawater in the cylinders twice in two years. ☹

Thanks

Mark

I want to replace my current downward facing mixing elbow with a u shaped riser as the top of my engine is level with the waterline. so the current mixing point is below it. It's also the same height as the top of the current waterlock. Pretty poor design, I gather, and probably the reason why I've had seawater in the cylinders twice in two years. ☹

Thanks

Mark