Dunx

Well-Known Member

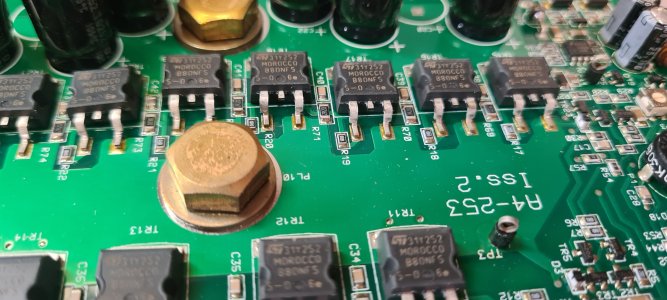

We have a single lewmar 48 electric winch on the boat which has stopped working. The fault seems to be in the ELS control box. The contactor in the box appears to work with energised suggesting the circuit board is the issue, I have replaced th deck switch. Does anyone have a contact for repair or refurbishment as £500 for a new box seems a bit steep. Thanks