BCarmena

New Member

Hello all,

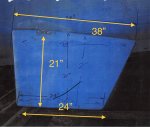

We purchased a 1969 Stephens Brothers aluminum last year. I am in the process of completing maintenance that has been neglected for many years. One item on the list is our Vosper stabilizer system. The system is non-functional but all of the equipment seems to be intact. The main problem is that someone has done a very disastrous job of attempting wiring repairs on the system. I am trying to rewire everything from the controls to the solenoids/position sensors. Unfortunately I have no documentation for the system. The boat came with most manuals but unfortunately not this one. I have opened the control modules just in case someone left a wiring diagram tucked inside as was common in those days but to no avail. Does anyone have and diagrams or manuals for this system or know where they can be had? The boat is coming out of the water this coming Monday as well and one of the items on the list is to completely disassemble the units, inspect, service, and reinstall. I am not completely sure how the units come off. I have heard of hydraulic tools to push them off of a taper but in the pictures that Vas posted in his retrofit thread it does not appear that the Vosper units are held with a taper like the Niaid Fins. What types of tools would I be needing to remove these? I have been a marine technician for many years however I have never had to remove one of these. Any help would be very much appreciated. Thanks in advance!

We purchased a 1969 Stephens Brothers aluminum last year. I am in the process of completing maintenance that has been neglected for many years. One item on the list is our Vosper stabilizer system. The system is non-functional but all of the equipment seems to be intact. The main problem is that someone has done a very disastrous job of attempting wiring repairs on the system. I am trying to rewire everything from the controls to the solenoids/position sensors. Unfortunately I have no documentation for the system. The boat came with most manuals but unfortunately not this one. I have opened the control modules just in case someone left a wiring diagram tucked inside as was common in those days but to no avail. Does anyone have and diagrams or manuals for this system or know where they can be had? The boat is coming out of the water this coming Monday as well and one of the items on the list is to completely disassemble the units, inspect, service, and reinstall. I am not completely sure how the units come off. I have heard of hydraulic tools to push them off of a taper but in the pictures that Vas posted in his retrofit thread it does not appear that the Vosper units are held with a taper like the Niaid Fins. What types of tools would I be needing to remove these? I have been a marine technician for many years however I have never had to remove one of these. Any help would be very much appreciated. Thanks in advance!

![2018-04-17-22.24[4web].jpg 2018-04-17-22.24[4web].jpg](https://ybw-data.community.forum/attachments/65/65162-2308797d5fe84f6ec9607a14c0214374.jpg?hash=Iwh5fV_oT2)