noob_sloop

New Member

Hello Team,

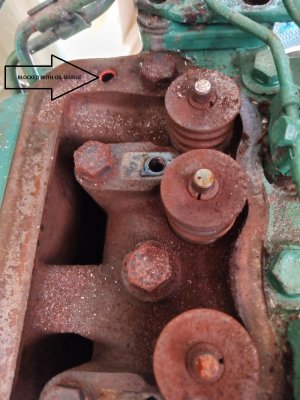

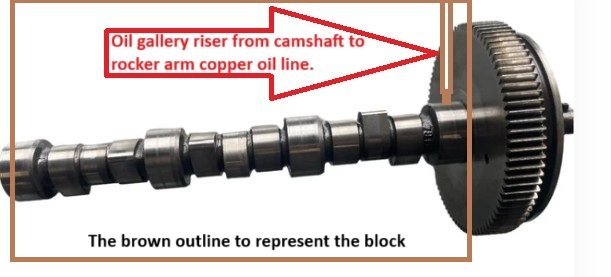

Today I’ve pulled out a head from my Penta 2003 (raw water cooled).

I’m wondering if someone has a diagram of the lubrication system for this engine.

I don’t see the oil discharge from the block into the head.

Is it normal? How exactly oil goes from the oil filter into the head (to lubricate rockers)?

This is the link to the YouTube video that shows no discharge through that hole.

Thank you.

Today I’ve pulled out a head from my Penta 2003 (raw water cooled).

I’m wondering if someone has a diagram of the lubrication system for this engine.

I don’t see the oil discharge from the block into the head.

Is it normal? How exactly oil goes from the oil filter into the head (to lubricate rockers)?

This is the link to the YouTube video that shows no discharge through that hole.

Thank you.