shortjohnsilver

Active member

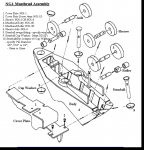

Mast head plate is alloy and incorporates a plate that secures down fore aft.

Rig-rite schematic diagram NG - 1 Unfortunately I can’t seem to include the diagram here.

To access the forestay stem ball fitting, this plate had to be removed. Removal also needed enable access to the main, foresail and spinnaker sheaves, within the mast head.

However, stainless steel screws securing the plate down had seized entirely. After 22 years this is not surprising. The screws had to be drilled out. However, the chap that did this for me, has been a bit over zealous and over drilled the alloy holes that receive the stainless steel screws opening them up and not straight at all. It’s difficult to explain but the plate also secures a spinnaker bracket are blocks for the spinnaker up lift and the whole assembly is/was robust enough that I could also use the skinny up lift for a safety security line when up the mast. This bracket and the plate have to totally strong and secure.

So, some have advised bolting through, with larger bolts, however the way the alloy is moulded this is impossible as there is insufficient room o secure nuts. Hence this moulding had been machined or screws that don’t pass entirely though the alloy casing.

I’m thinking that I might be able to fill the holes now existing, with J B Weld a cold weld remedy, or other recommended product, and once totally cured and as hard as the alloy it’s in, tap in new correctly sized screw holes. The bumph I have read from J B Weld suggest that the product will be harder than the alloy it’s replacing and therefore suitable for a tap and dye process to re introduce the right thread.

Is this right and an approach suitable to put right the problem?

As an alloy moulded fitting, I’m not sure that heat welding would be possible, as to introduce the heat necessary to weld into the holes will fracture the alloy moulding completely or reduce its strength far too much that it would fail.

To be honest I wish I’d left the whole lot alone! But the rigger whose replacing the standing rigging wanted the stem ball out and removal of the plate was necessary.

Rig-rite schematic diagram NG - 1 Unfortunately I can’t seem to include the diagram here.

To access the forestay stem ball fitting, this plate had to be removed. Removal also needed enable access to the main, foresail and spinnaker sheaves, within the mast head.

However, stainless steel screws securing the plate down had seized entirely. After 22 years this is not surprising. The screws had to be drilled out. However, the chap that did this for me, has been a bit over zealous and over drilled the alloy holes that receive the stainless steel screws opening them up and not straight at all. It’s difficult to explain but the plate also secures a spinnaker bracket are blocks for the spinnaker up lift and the whole assembly is/was robust enough that I could also use the skinny up lift for a safety security line when up the mast. This bracket and the plate have to totally strong and secure.

So, some have advised bolting through, with larger bolts, however the way the alloy is moulded this is impossible as there is insufficient room o secure nuts. Hence this moulding had been machined or screws that don’t pass entirely though the alloy casing.

I’m thinking that I might be able to fill the holes now existing, with J B Weld a cold weld remedy, or other recommended product, and once totally cured and as hard as the alloy it’s in, tap in new correctly sized screw holes. The bumph I have read from J B Weld suggest that the product will be harder than the alloy it’s replacing and therefore suitable for a tap and dye process to re introduce the right thread.

Is this right and an approach suitable to put right the problem?

As an alloy moulded fitting, I’m not sure that heat welding would be possible, as to introduce the heat necessary to weld into the holes will fracture the alloy moulding completely or reduce its strength far too much that it would fail.

To be honest I wish I’d left the whole lot alone! But the rigger whose replacing the standing rigging wanted the stem ball out and removal of the plate was necessary.