LadyInBed

Well-Known Member

The fly in the ointment might not be air moisture, fitting out the boat on the hard could put stresses in a different direction to when it's afloat.But I don't think moisture will be a problem as it is all fiber-glassed.

The fly in the ointment might not be air moisture, fitting out the boat on the hard could put stresses in a different direction to when it's afloat.But I don't think moisture will be a problem as it is all fiber-glassed.

The fly in the ointment might not be air moisture, fitting out the boat on the hard could put stresses in a different direction to when it's afloat.

He could always fit a sliding door to the heads like we have. That won't jam?I spoke to the owner (One Rob Stuart, the father of Andrew, the designer of the limbos)of a 3/4 tonner called Dingo. Built years ago. The designer stretched a cord through the middle of the boat from bow to stern & pulled it taught. He measured keel to cord & noted dimension.

They then set the rigging & the dimension had changed by 1.5 inches. Apparently the designer felt this extremely good on a race boat of the era.

I would imagine that modern AWBs move even more. I know that the floor of mine lifted .5 inches when badly chocked in Inverness one year (never happens in Bradwell). I do not know the design of the OPs boat & the door may be fitted across the hull , not longitudinally. But movement must happen & it will be accentuated in waves

I would imagine that modern AWBs move even more. I know that the floor of mine lifted .5 inches when badly chocked in Inverness one year (never happens in Bradwell). I do not know the design of the OPs boat & the door may be fitted across the hull , not longitudinally. But movement must happen & it will be accentuated in waves

Correction. Rob Stuart is Andrew's older brother, their dad was Bob Stuart. He was the owner of Dingo and Rob and Andrew regularly crewed onboard.I spoke to the owner (One Rob Stuart, the father of Andrew, the designer of the limbos)of a 3/4 tonner called Dingo. Built years ago. The designer stretched a cord through the middle of the boat from bow to stern & pulled it taught. He measured keel to cord & noted dimension.

They then set the rigging & the dimension had changed by 1.5 inches. Apparently the designer felt this extremely good on a race boat of the era.

I would imagine that modern AWBs move even more. I know that the floor of mine lifted .5 inches when badly chocked in Inverness one year (never happens in Bradwell). I do not know the design of the OPs boat & the door may be fitted across the hull , not longitudinally. But movement must happen & it will be accentuated in waves

I get the impression Coopec is not listening to the advice

The mast compression loads will bend that bulkhead. Even steel I beams bend/deflect.

A door with a tight fit will be compressed, somewhere, and the glass/epoxy coating will crack and the moisture that is then able to be absorbed will allow the door to distort further.

Give the door a loose fit.

and/or

Scrap the existing door and build a new one from foam.

Jonathan

It's entirely possible. Plywood stress/strain diagram...

0.1% might not sound much, but on a 2m bulkhead that's 2mm. Boatbuilders build doors with a noticeable gap to the frame for exactly this reason. A non jamming door is much more important than keeping farty noises out.

So you'd agree the 3-4mm gap I am planning is quite reasonable?

I spoke to the owner (One Rob Stuart, the father of Andrew, the designer of the limbos)of a 3/4 tonner called Dingo. Built years ago. The designer stretched a cord through the middle of the boat from bow to stern & pulled it taught. He measured keel to cord & noted dimension.

They then set the rigging & the dimension had changed by 1.5 inches. Apparently the designer felt this extremely good on a race boat of the era.

I would imagine that modern AWBs move even more. I know that the floor of mine lifted .5 inches when badly chocked in Inverness one year (never happens in Bradwell). I do not know the design of the OPs boat & the door may be fitted across the hull , not longitudinally. But movement must happen & it will be accentuated in waves

Ding ding. Sense of humour failure!For heaven's sake why do you say that?

Looks like a stretched version of my 1980 Ray Wall designed Nicholson39 with a long keel.Racing yachts would be much more lightly constructed (and therefore highly stressed) than a heavy displacement cruising yacht.I would expect a racing yacht (or lightly built production yacht ) to flex more than HD cruising yacht.

NOTE

It would help if YBW gave some basic information in the members profile (as other forums do) .

I am building a fiberglass Roberts 43 Mauritius

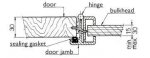

Regardless of the gap, it would be more effective to make the door close flush against the jamb. You could even have a foam or rubber 'gasket' to seal it further if you are obsessional.