sailorbenji

Well-Known Member

Hi, one for the incredible hive-mind here....

We have a watermaker on board, that can utilise two tank level switches (one at the bottom, one at the top) to both trigger water making and stop water making respectively.

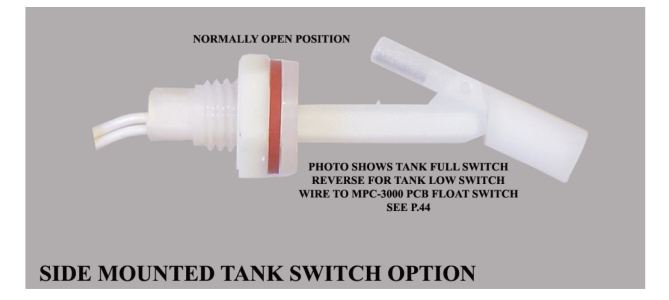

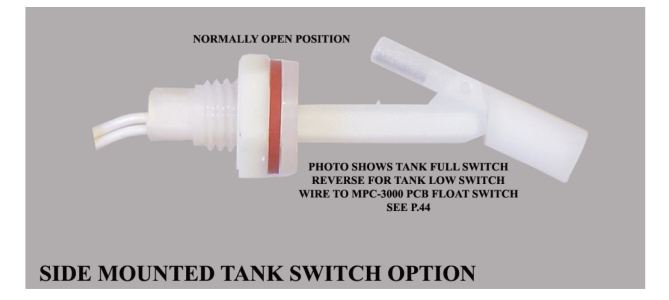

The suggested tank level switches are this kind, simple volt-free contacts mounted in such a way that they are NO and close when 'triggered'.

My issue is I cannot get to the side of the tanks to install 2 additional switches like this, but we do have a fully functioning analogue tank gauge reading from a resistive type float sender, 0-180 ohm I believe.

I wondered, and appreciate this may mean delving into a bit of an electrickery project, if anyone could recommend some way that we could use the resistive sender to generate full and empty triggers, which we could wire into the water maker instead of these dedicated switches?

I have some experience with ESP devices etc, but am by no means a programmer.....

Any suggestions, or similar projects (or even products) that might do this, please point me in the direction...or of course any other solutions.

Thanks, Ben

We have a watermaker on board, that can utilise two tank level switches (one at the bottom, one at the top) to both trigger water making and stop water making respectively.

The suggested tank level switches are this kind, simple volt-free contacts mounted in such a way that they are NO and close when 'triggered'.

My issue is I cannot get to the side of the tanks to install 2 additional switches like this, but we do have a fully functioning analogue tank gauge reading from a resistive type float sender, 0-180 ohm I believe.

I wondered, and appreciate this may mean delving into a bit of an electrickery project, if anyone could recommend some way that we could use the resistive sender to generate full and empty triggers, which we could wire into the water maker instead of these dedicated switches?

I have some experience with ESP devices etc, but am by no means a programmer.....

Any suggestions, or similar projects (or even products) that might do this, please point me in the direction...or of course any other solutions.

Thanks, Ben