Lomax

Well-Known Member

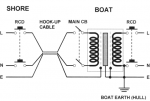

Any reason you prefer half a ton of copper and iron instead of a galvanic isolator?

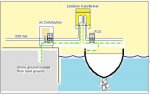

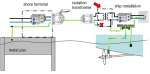

My impression is that isolation transformers are "better" than galvanic isolators (diodes), both in terms of function (GIs allow 0.7V galvanic charge) and reliability (diodes die). Weight is not an issue on my boat; she weighs in at 12t and has almost a ton of ballast (in 60kg steel billets). The 3600W Victron weighs a mere 23kg, and will share room with a Perkins 6.354 diesel engine which weighs 600kg, and a 500L diesel tank. I will also carry something like 700L of freshwater, and 1000Ah of flooded lead acid batteries. Basically, what I'm trying to say is that the isolation transformer is actually one of the lightest objects aboard

Last edited: