schmidp

Member

Hello,

I am trying to get the old steel steel boat I bought last summer working and I have trouble with my reverse gearbox slipping, so the guys in the marina suggested that maybe the propeller is loose, so I dived down (still a bit cold at 16C) and took a short video of the prop.

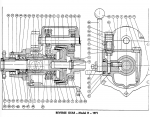

Apparently no-one here has seen a system like this before were the shaft moves through the propeller. What is that kind called? So I could look for some drawings online to understand it better.

How is the prop fixed to the shaft? Can't be a screw as the prop stays and the shaft moves and there does not seem to be a nut at the end.

I did not have the boat out of the water yet as I want to get the gearbox and engine working properly before I get on with the cleanup up the hull.

The shaft is 25mm btw, now that I look at the picture, does a 2 blade propeller like this seem big enough for a 5t 9m steel boat?

I am trying to get the old steel steel boat I bought last summer working and I have trouble with my reverse gearbox slipping, so the guys in the marina suggested that maybe the propeller is loose, so I dived down (still a bit cold at 16C) and took a short video of the prop.

Apparently no-one here has seen a system like this before were the shaft moves through the propeller. What is that kind called? So I could look for some drawings online to understand it better.

How is the prop fixed to the shaft? Can't be a screw as the prop stays and the shaft moves and there does not seem to be a nut at the end.

I did not have the boat out of the water yet as I want to get the gearbox and engine working properly before I get on with the cleanup up the hull.

The shaft is 25mm btw, now that I look at the picture, does a 2 blade propeller like this seem big enough for a 5t 9m steel boat?