peterhull

Well-Known Member

I have a cutter rigged trailer sailer under restoration.

I bought new hanked on sails purposely avoid having install furlers to try to keep things simple.

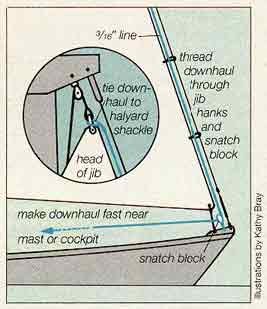

A simple block on the foredeck with line to the head of the sail and led aft would work I guess but is there a more simple solution to avoid to more lines over the foredeck.

Has anyone got an alternative solution?

One thought I had was a reversible halliard winch that can pull in both directions . Pull the sail up and pull it down.

Any thoughts please?

I bought new hanked on sails purposely avoid having install furlers to try to keep things simple.

A simple block on the foredeck with line to the head of the sail and led aft would work I guess but is there a more simple solution to avoid to more lines over the foredeck.

Has anyone got an alternative solution?

One thought I had was a reversible halliard winch that can pull in both directions . Pull the sail up and pull it down.

Any thoughts please?