TactilePaul

Well-Known Member

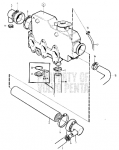

HI, so my Step Mother is in Alderney with a Volvo MD2030 loosing water, she has discovered that the 'radiator cap' is corroded , or rather the metal surrounding it, it has an auxiliry expansion / filling point and of course a loop to the HW cylinder.

that the 'radiator cap' is corroded , or rather the metal surrounding it, it has an auxiliry expansion / filling point and of course a loop to the HW cylinder.

My Question, seeing as they are on a rock, is, Would it be ok to run engine like this, if someone keeps topping up through the broken cap?, or is there pressure here that will pump the water out?

They are trying to get it sorted whilst there, but also making plans for possible sail home maybe just using engine for last 5 mins, another question, how long till a diesel overheats with no coolant????

any help appreciated,

Thanks.

that the 'radiator cap' is corroded , or rather the metal surrounding it, it has an auxiliry expansion / filling point and of course a loop to the HW cylinder.

that the 'radiator cap' is corroded , or rather the metal surrounding it, it has an auxiliry expansion / filling point and of course a loop to the HW cylinder.My Question, seeing as they are on a rock, is, Would it be ok to run engine like this, if someone keeps topping up through the broken cap?, or is there pressure here that will pump the water out?

They are trying to get it sorted whilst there, but also making plans for possible sail home maybe just using engine for last 5 mins, another question, how long till a diesel overheats with no coolant????

any help appreciated,

Thanks.