lustyd

Well-Known Member

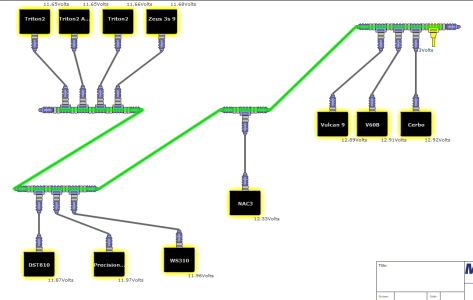

Just faffing with the network today and while we’re still in spec, we do have voltage drop that seems excessive. The whole backbone is less than 20m, probably more like 15m using Garmin cables. Drop cables are all very short. Annoyingly the power feed is at one end and the instruments are at the other which is probably the main issue.

Has anyone else checked the voltage on their network and can comment on what would be normal? I don’t really fancy a full troubleshooting exercise and would really prefer not to move the power input as it would require a lot of boat yoga and another long power cable run.

We’ve not had any real issues but the low voltage alarm has tripped twice this year when we had all the things running at once under sail.

Has anyone else checked the voltage on their network and can comment on what would be normal? I don’t really fancy a full troubleshooting exercise and would really prefer not to move the power input as it would require a lot of boat yoga and another long power cable run.

We’ve not had any real issues but the low voltage alarm has tripped twice this year when we had all the things running at once under sail.