Andy Kirkpatrick

New Member

Hi

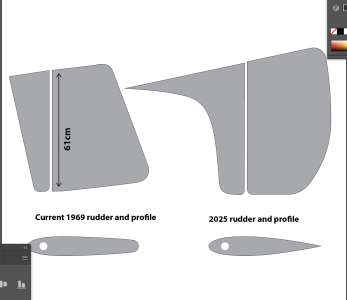

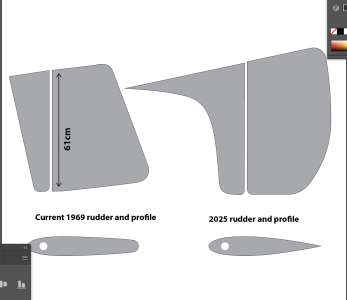

I'm currently working on building a new skeg and rudder for a 1969 bilge keel Hurley 22 bilge. I could just copy what's already there, but seeing as it's a 50 year old design, I wondered if I could make it more contemporary, mostly by giving the rudder, which is like a brick, more of an aerofoil profile. I sketched something based on a Spitfire's wing, and made the skeg bigger and more profiled, but I now can see the bottom edge of the rudder is much shorter, with the longest chord around the middle. I'm not a marine architect, and the hull speed is only 5 or so knots, so maybe I'm just overthinking it?

I live on the West Coast of Ireland, so I want something West Coast proof.

Any advice would be appreciated.

Thanks

I'm currently working on building a new skeg and rudder for a 1969 bilge keel Hurley 22 bilge. I could just copy what's already there, but seeing as it's a 50 year old design, I wondered if I could make it more contemporary, mostly by giving the rudder, which is like a brick, more of an aerofoil profile. I sketched something based on a Spitfire's wing, and made the skeg bigger and more profiled, but I now can see the bottom edge of the rudder is much shorter, with the longest chord around the middle. I'm not a marine architect, and the hull speed is only 5 or so knots, so maybe I'm just overthinking it?

I live on the West Coast of Ireland, so I want something West Coast proof.

Any advice would be appreciated.

Thanks