warwicksail

Well-Known Member

Hi can anyone run through the procedure for removing the above impeller. will be a great help can find my manual anywhere.

Paul

Paul

I found it to be very easy with a hook on the end of a piece of wireAssuming it's the same as mine (2006 model)

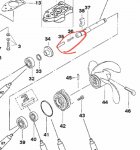

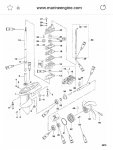

Pull off a rubber cap on the side of the bottom of the drive leg and undo a screw that joins the two parts of the gear linkage. Undo two bolts and take off lower section of drive unit: another 4 bolts then become visible on a small casing over impeller. Undo and take out impeller and metal ring in which it runs. Dead easy so far.

There is a small keyway that drops out as you take off the casing over impeller. This must be back in place as you reassemble. Stick in place with grease or hold witha bit of string to get impeller case back on. Not too difficult.

Then comes the difficult bit - getting the lower drive leg back on. You have to line up the drive shaft and the join in the gear linkage AND the water feed pipe, and that is very, very awkward, especially with fat fingers, as you are working inside a small hole (that the rubber cap goes on) to line them up. I did this all a couple of weeks ago and after spending an hour trying took it to a local outboard shop expecting them to have a special tool or jig or something.

"It's just a bugger of a job" they said, "we curse every time. Fiddle with a bit of bent wire".