thinwater

Well-Known Member

I believe your thought is correct - most people use their furler as a device to reef the headsail - other wise you have a head sail that can only be used, sensibly, upto 20/25 knots and then needs to be furled completely - leaving you with no headsail at all. Unless of course you are monied and have an inner forestay or 2 furlers.

Trying to remove a large unfurled headsail from a foil - is simply a non starter. The sail will be flogging, the friction between sail and foil will lock the sail solid. If you are trying to do this it is because the wind is up and seas have built. If you get the sail off the foil exactly how are you meant to handle this monster on the deck? Sometimes I think the suggestions are made by people who have never been 'out at sea' and the suggesting are impossible and dangerous.

Most people are sailing as a cruising couple or family not as a troupe of gorillas. If the task cannot be completed largely single handed - the task cannot be completed.

Like many devices on the family yacht a furler is a god send and makes family sailing possible to all of us - this is until the furler, does not furl. then its a disaster waiting to happen (and the family will never come sailing with you again). Check your furler, and the other critical bits of kit, before you get into panic mode. If you furl your headsail under tension (full of wind) it will furl tightly and you will find that if you do not have extra turns and you cannot furl completely. You need extra turns on the drum - which also allows you to 'furl' the sheets round the sail better securing the sail (as mentioned on an earlier post).

I see maybe 2-3 headsails flogged to death and torn to ribbons for headsails that have slowly, or rapidly, unfurled due to inattention in a stronger wind event. You lose money in a destroyed sail and upset the neighbours from the noise of the flogging sail (at 3am).

Play with your furler and line on a calm day in the marina, on the swing mooring. Add a few extra turns on the drum, make sure the drum loads evenly (or the furling line can jamb in the 'cage').

Jonathan

Yes... and no.

I commonly use my genoa, deeply reefed, in 30 knots. The sailmaker was brilliant, and the luff padding and clew maintained good shape right down to a hankercheif. Best cruising cut I have seen. 2-3 reefs in the main and just a bit of jib is a good combination.

Hauling it down in a blow... depends. I've done it once in 20 knots and once in a bit more. The second was actually easier because I was more experienced, but neither was epic. I blanketed it behind the main, kept some tension on the sheet, and just worked it down. No more than a few minutes. However, this is LOT easier on the broad tramp of a cat than on a mono!

The cause? The furler bearings (plastic) failed during a cruise. The first was a surprise, the second less so. I replaced them with stainless, used a good waterproof grease, and added a drip seal. That did the trick for 10 years and counting.

---

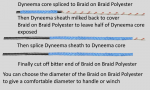

But yes, they have their problems. On my F-24, the jib furler is brilliant, but I need to replace the line with something small on the reacher. Sometimes I can roll it tight enough without running out of line. Most likely it will be Dyneema covered with polyester on the tail.