Daydream believer

Well-Known Member

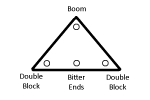

In the picture of that boat with the spinnaker the boom is being held by the windward mainsheet. The leeward one is slack. That suggests that he is not using that one to assist the vang. So in that situation, one might ask what is the point of the arrangement?

Last edited: