Lomax

Well-Known Member

Hi all,

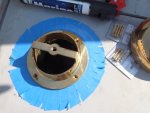

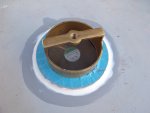

I would like to install a beefy vent in the forward cabin roof, accommodating a 12V fan for forced ventilation. I've seen a lot of "solar vents" around, but I'm looking for something much more powerful, with a proper exhaust fan that can shift a lot of air when needed. I'd also prefer if the internal structure was as low profile as possible; I already have plenty of fittings on deck which protrude 10-15cm, while ceiling height inside the cabin is severely restricted - much better for me if the bulk of the ventilator ends up on the outside. Anyone have any suggestions?

I would like to install a beefy vent in the forward cabin roof, accommodating a 12V fan for forced ventilation. I've seen a lot of "solar vents" around, but I'm looking for something much more powerful, with a proper exhaust fan that can shift a lot of air when needed. I'd also prefer if the internal structure was as low profile as possible; I already have plenty of fittings on deck which protrude 10-15cm, while ceiling height inside the cabin is severely restricted - much better for me if the bulk of the ventilator ends up on the outside. Anyone have any suggestions?

Last edited: