Pedro araujo

New Member

Problems in running at low speed long periods with MANs 1360 from 2004! Does it damage the engines?

Windmilling the gear box is a no no with Twin Disc .There is way ( again read the handbooks ) of locking the shaft .Will it steer straight on one engine?

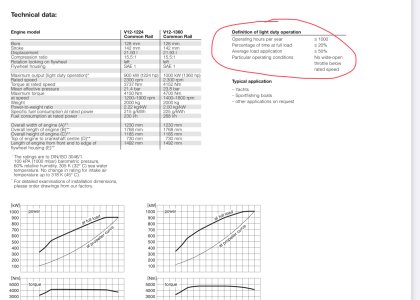

We already discussed this.Tick over ie 600 rpm for long periods is a no no according to the manual with MAN s from that era

If the OP has MAN engines rated for 1360hp, they are CR for good (LE423).I have a pair of 2876 s le 401 . Rated @ 700 Hp .From 2003 so identical tech wise just 1/2 the size .

[...]

It’s not clear from your post if yours are CR as you haven’t given the full engine designation codes .

2004 was a cross over yr when CR was starting to be rolled out .

I made the point , advised him to follow the manufacturers manual on this , the duty cycle .Which it seems ( according to you ) i posted the correct screen shots ,in case he hasn’t got access .We already discussed this.

The recommendation you are referring to is specifically related to unloaded idling, i.e. with gearbox in neutral.

A time limit to running the engines at low rpm with the gear engaged just doesn't exist.

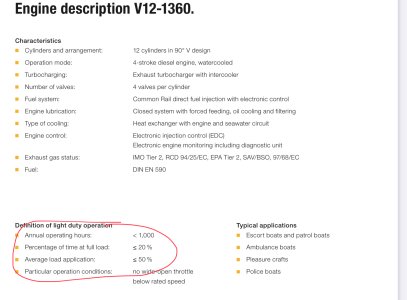

If the OP has MAN engines rated for 1360hp, they are CR for good (LE423).

In fact, those were the only 1360hp engines ever built by MAN.

BTW, very different from your so-called EDC engines, which simply adopted an electronic governor on otherwise mechanical engines.

A solution that they used just for a few years in all their engines aside from V8s, which was a sort of testbed for the CR they eventually used also on R6, V10 and V12. The V12 comparable to yours, in those days, were the LE404, rated for 1300hp.

CR adoption was a much more radical development, which came also with others, like the 4 valves heads, among other stuff.

Just saying, 'cause this is irrelevant to OP question.

Regardless of age and technology, there's no such thing as a MAN engine for which the manufacturer officially recommend to avoid using it at low RPM for long time - as simple as that.

And while I can't be positive about other manufacturers, I have a funny feeling that this is also true for them all!

“ Regardless of age and technology, there’s no such thing as a car for which the manufacture officiallyRegardless of age and technology, there's no such thing as a MAN engine for which the manufacturer officially recommend to avoid using it at low RPM for long time - as simple as that.

And while I can't be positive about other manufacturers, I have a funny feeling that this is also true for them all!

That isn't what Mapis said, or what the OP asked.“ Regardless of age and technology, there’s no such thing as a car for which the manufacture officially

recommends to avoid using it at max speed driving off the edge of a cliff - simple as that .

And while I can’t be positive about other manufacturers , I have a funny feeling that this is also true for them all “

Q - from the Op = Problems driving a car at max speed off the edge of a cliff , does it damage you or the car ?

@ MapishM let’s stick to what the manufacturer actually says how ever vague and open to multiple interpretations .

As opposed what’s been omitted .

That sounds a little expensive.My view FWIW , my 0.02 p worth .

Yes it is it like a double negative logic thingy .That isn't what Mapis said, or what the OP asked.

Just drivel.

That sounds a little expensive.

That couldn't be more far from the truth.Mapish is saying because the manufacturer did NOT say it’s ok to do it…..then it’s IS ok to presume it’s ok to do it .

We don’t know exactly what he meant by low running or the exact spec of the engines .We both have had to join a few dots up .That couldn't be more far from the truth.

YOU said "Tick over ie 600 rpm for long periods is a no no according to the manual with MAN s from that era".

I simply pointed out that what MAN suggest is to avoid this when not in gear, because I don't think that's what the OP meant.

As opposed to that, there's no MAN suggestion anywhere to avoid running at low rpm for long period.

What's the part of this very simple observation that you don't understand?