Little Dorrit

Well-Known Member

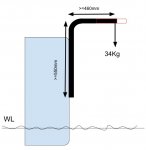

I am looking for some help with structural load bearings. I want to put davits on the transom to support an older ‘lift up’ Aries wind vane which weighs 34Kg. Newer (and I assume) lighter models are attached using davits made from two lengths of 38.1 x 6.35mm aluminium tubing clamped to the transom with 4 x 38mm pipe clamps and 8 x 316 M8 bolts. These are attached to the transom and a 90-degree bend allows them to support the wind vane. The weight will hang about 350mm from the bend and 450mm from the transom. On the newer Airies models, this is an acceptable method of installation but I wondered if this would support my 34Kg version?