STOL71

Well-Known Member

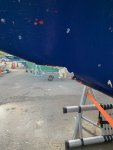

I've got little keel repair to do, the damage is about fist size. Let's just assume the damage is the result of hitting a shipping container at about 6 knots. I've a few images attached. I was thinking of grinding it out, cover the hole in expoxy resin, build it up with westexpoxy filler, then cover in fibre glass matting then fair it down, cover in exoxy, then primer and antifoul. Is that about the right course of action? The damage is not structural. Thank you for your help.