BruceK

Well-Known Member

Put a new one on on Sat as the old one was getting a bit worn. Came without the diode that sits inline both magnet wires and both wires are black.

So I snipped off the old inline diode and connected it in parallel as on previous clutch.

Clutch spacers were slightly too small to fit on shaft so reused old and checked. It doesn't have a perfect gap but can freewheel without grinding.

Tested it and it worked fine.

All through the rough waters it was on the dime. Perfect operation. Then when nearing the journey's end coming onto the plane the clutch would engage per normal, hand over to the turbo normal, SC disengages fine. No further spinning.

About 30 seconds later you notice the synchroniser needle flick, 5 seconds later, flick. Then the engine fuse in the black box blows.

Come down below 1700 rpm and you can pop the fuse back in. Get back on the plane SC hands off to turbo, flick flick pop. You get it.

Unplug the clutch and the engines run like a peach.

So it's the new SC Clutch.

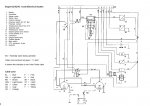

Diode? (As it was detatched with plug any polarity would have been retained.

Is there a + or - wire to the electromagnet

Very odd. Any words of wisdom appreciated before I badger VolvoPaul. I think he must be sick of KADs by now.

So I snipped off the old inline diode and connected it in parallel as on previous clutch.

Clutch spacers were slightly too small to fit on shaft so reused old and checked. It doesn't have a perfect gap but can freewheel without grinding.

Tested it and it worked fine.

All through the rough waters it was on the dime. Perfect operation. Then when nearing the journey's end coming onto the plane the clutch would engage per normal, hand over to the turbo normal, SC disengages fine. No further spinning.

About 30 seconds later you notice the synchroniser needle flick, 5 seconds later, flick. Then the engine fuse in the black box blows.

Come down below 1700 rpm and you can pop the fuse back in. Get back on the plane SC hands off to turbo, flick flick pop. You get it.

Unplug the clutch and the engines run like a peach.

So it's the new SC Clutch.

Diode? (As it was detatched with plug any polarity would have been retained.

Is there a + or - wire to the electromagnet

Very odd. Any words of wisdom appreciated before I badger VolvoPaul. I think he must be sick of KADs by now.