Norman_E

Well-Known Member

I must be missing something here. How can I put a 10mm wire rope and thimble through a motor-cycle chain link? I'm utterly confused!

Maybe the answer lies in your statement "if you have the space for the parts." If I understand you correctly then I don't have the space.

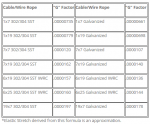

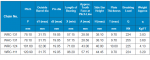

]View attachment 81439 View attachment 81438

You don't put the rope and thimble through the chain, but link the two with a pair of steel strips and nuts & bolts.