You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is there an economoical alternative to Ronstan/Harken/Lewmar sheave blocks?

- Thread starter coopec

- Start date

LadyInBed

Well-Known Member

Not sure if Allen do that size

Allen Blocks

Allen Blocks

MikeCC

Well-Known Member

Selden?

coopec

N/A

I have emailed Allen Bros. (I think Jon Neeves mentioned they have an Australian outlet in Sydney)Not sure if Allen do that size

Allen Blocks

Thanks.

Neeves

Well-Known Member

Allen focus much of their business on dinghies - I think that is their background - but do appear to be moving 'up-size'.

I agree - blocks do seem expensive.

If you have the time and skill:

Buy the sheaves, even make the sheaves, then make you own blocks.

I have a similar quandary, different application, and have come to the same conclusion (they are expensive). I have some sheaves of the correct sort of size - and I can buy sheaves of the same sort of size (but better, from Allen and I am sure others) and am planning to make my own blocks. Mine are simple single sheaved blocks and I will not 'bother' polishing the stainless (so they will not look nearly so glamorous). But making my own blocks - I can customise them to my specific requirement and if I get it wrong - I've only wasted my own time (as I already have the sheaves). If it works out I can replace my, cheap, sheaves with better Allen sheaves.

I collect marine waste. My sheaves come from blocks on a previous yacht where the block exploded - leaving me with perfect sheaves and no home - now they might have a home and my investment in keeping them is going to pay off.

Its worth looking at block 'development' there are some interesting innovative ideas being used - and some incorporate soft shackles (or dyneema) and the use of textile seems sensible and not contrived.

Take care, stay safe

Jonathan

I agree - blocks do seem expensive.

If you have the time and skill:

Buy the sheaves, even make the sheaves, then make you own blocks.

I have a similar quandary, different application, and have come to the same conclusion (they are expensive). I have some sheaves of the correct sort of size - and I can buy sheaves of the same sort of size (but better, from Allen and I am sure others) and am planning to make my own blocks. Mine are simple single sheaved blocks and I will not 'bother' polishing the stainless (so they will not look nearly so glamorous). But making my own blocks - I can customise them to my specific requirement and if I get it wrong - I've only wasted my own time (as I already have the sheaves). If it works out I can replace my, cheap, sheaves with better Allen sheaves.

I collect marine waste. My sheaves come from blocks on a previous yacht where the block exploded - leaving me with perfect sheaves and no home - now they might have a home and my investment in keeping them is going to pay off.

Its worth looking at block 'development' there are some interesting innovative ideas being used - and some incorporate soft shackles (or dyneema) and the use of textile seems sensible and not contrived.

Take care, stay safe

Jonathan

Wing Mark

Well-Known Member

I once needed some odd blocks for a dinghy.

I turned the sheaves out of acetal, with stainless bearings sold for skateboard wheels.

The sides of the blocks were a mixture of plastic and stainless sheet.

These days I would think about Carbon Fibre for the plates.

But 15mm rope implies strong engineering.

I turned the sheaves out of acetal, with stainless bearings sold for skateboard wheels.

The sides of the blocks were a mixture of plastic and stainless sheet.

These days I would think about Carbon Fibre for the plates.

But 15mm rope implies strong engineering.

rotrax

Well-Known Member

If Brent Swain was still active on this forum he could tell you how to make a block in 20 minutes for five bucks.

Using plastic cutting boards and scrap sheet stainless steel.

I know he can do this, he kept telling me so.............................

Using plastic cutting boards and scrap sheet stainless steel.

I know he can do this, he kept telling me so.............................

fredrussell

Well-Known Member

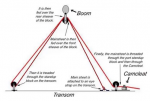

Looking at that mainsheet setup, I can’t see how you adjust boom to port/starboard to trim sail. Am I missing something, or are you happy to do without that adjustment?

Neeves

Well-Known Member

I once needed some odd blocks for a dinghy.

I turned the sheaves out of acetal, with stainless bearings sold for skateboard wheels.

The sides of the blocks were a mixture of plastic and stainless sheet.

These days I would think about Carbon Fibre for the plates.

But 15mm rope implies strong engineering.

I had a quick search for carbon fibre sheet to make the plates - maybe its a problem with Australia - but carbon fibre sheets are extortionate. If you had a true weight fetish and were top of you game building and sailing foiling Moths I'm sure if might be the answer - but it seems (from the 10 minutes I spent searching) only for those with bottomless pockets.

I'd stick with 316 stainless (or maybe 2205 Duplex stainless).

But, never say never - if its cheap in the UK - I'm interested

Jonathan

Neeves

Well-Known Member

Looking at that mainsheet setup, I can’t see how you adjust boom to port/starboard to trim sail. Am I missing something, or are you happy to do without that adjustment?

As far as I can ascertain Coopec has lifted that image from a Jenny - so I assume just an illustration of his current thinking - but he does say he has not yet fixed his mainsheet design. Maybe the cost of the blocks has crystallised his mind - and he is looking for inspiration (as I might in his position (clean sheet of paper - finite size of wallet

I do agree I cannot see how you pull the main, easily, to windward - but you can dump the main, quickly, to leeward (as long as you can release the mainsheet from that cleat). How often do you have the boom above 'amidships'?

Take care, stay safe

Jonathan

coopec

N/A

I've had laser cutting done when I made up the bow roller but that was something like 8mm 316. (3/4mm would be a cinch)

I have a bar bender and my Son has a lathe although I'd probably buy the sheaves.(maybe that is easier said than done)

As Wing Mark points out "But 15mm rope implies strong engineering ". Does that mean I have to go for something like a brass bearing rather than ball bearings?

I have a bar bender and my Son has a lathe although I'd probably buy the sheaves.(maybe that is easier said than done)

As Wing Mark points out "But 15mm rope implies strong engineering ". Does that mean I have to go for something like a brass bearing rather than ball bearings?

coopec

N/A

I had all the sails, roller furler and masts and booms all fitted out by Taskers. The sail-maker was Steve Hartley (who has crewed on about X5 Sydney/Hobarts). When they said I wouldn't need a traveler I didn't question them. ?

Does this yacht need a traveler?

Running rigging - Wikipedia

(I know I've seen yachts without travelers)

Does this yacht need a traveler?

Running rigging - Wikipedia

(I know I've seen yachts without travelers)

coopec

N/A

"You’ll be able to tell from the photos that a few minor modifications were made above the gunwale: A gentle extension to 37 feet, a safe centre cockpit allowed for a roomy stern cabin and very practical stern deck, the boom was extended to allow a full tent over the cockpit when anchored up in the rain, and the mainsheet was modelled on the Cornish 3-point block/tackle approach to eliminate a traveller and simplify mainsheeting for family use. Down below, the theme of family-use continued with the ceiling height slightly raised to allow for the men over 6 feet, the Heads were moved athwart the engine and closer to the main hatch, and all bunks allow 6’6” length.

Boatplans ROBERTS 36

The set-ups I have seen were 3 point - center, Port and Starboard

Thoughts on mainsheet traveler V’s Double blocked mainsheet?

Boatplans ROBERTS 36

The set-ups I have seen were 3 point - center, Port and Starboard

Thoughts on mainsheet traveler V’s Double blocked mainsheet?

Last edited:

Wing Mark

Well-Known Member

I had half a metre of carbon cloth kicking around, and a pot of epoxy.I had a quick search for carbon fibre sheet to make the plates - maybe its a problem with Australia - but carbon fibre sheets are extortionate. If you had a true weight fetish and were top of you game building and sailing foiling Moths I'm sure if might be the answer - but it seems (from the 10 minutes I spent searching) only for those with bottomless pockets.

I'd stick with 316 stainless (or maybe 2205 Duplex stainless).

But, never say never - if its cheap in the UK - I'm interested

Jonathan

So I made a bit of carbon sheet!

A lot of people have done this.

Lay up a couple of layers of cloth on a polythene covered board . press it with another sheet and some weights,

When set, cut to shape, glue together, add more layers.

It can be quite economical, especially compared to ordering stainless plate on a retail basis.

Wing Mark

Well-Known Member

These two mainsheets are very different.

Assuming the blocks in the phot don't slide on the white/blue rope, this system won't provide much leach tension as soon as the boom is off the centre line.

It's a fine system, I have iessentially the same on a dinghy, but I have a 16:1 vang bending a carbon boom to do the leach tension.

The system in the sketch, if you move the boom off centre, you have 2 strands of the main mostly pulling down and 2 pulling to windward and down.

Again it's a fine system, great if you don't have a strong enough boom for the kicker to do all the leach tension up wind, and your rig is designed for the boom not to be so close to the centreline.

I have raced with a sheet that works like that, on a boat with a wooden boom.

Yachts of nay size would need massive booms to be totally 'vang sheeted', like some dinghies where the sheet ends up horizontal on windy days.

If you look at some dinghies, they can have a system a bit like the photo, but the blocks move on the white/blue ropes between knots, so the sheet has a balance of moving the boom in and providing leach tension.

It can be tweaked to alter the balance by varying the length of the strops/horse and the position of the knots!

So when you ease the sheet, what balance do you want between letting the top twist off and the whole main hinging like the proverbial barn door?

My cruising boat is small with a stout boom and the mainsheet goes to a single U bolt on the cockpit sole. I will upgrade the kicker/vang a bit, but it's a cruising boat after all.

Having said that, my wife finds the sheet hard work close hauled so changes are not ruled out!

dunedin

Well-Known Member

As wing mark says, the diagram and the photo have very different setups. And neither of which looks ideal to me.

And the optimum system will depend on whether cockpit/transom mounted, like the diagram, or ahead of the cockpit, like the photograph.

Need to design the sheeting system fully before investing in expensive pulleys. We have a track ahead of the hatch, with mainsheet led back to helm, using all Ronstan blocks, which is ideal for us - but not the cheapest.

Then once designed and satisfied (possibly using a mock-up with thin rope and dinghy pulleys), be prepared to invest in quality blocks for this application. The forces after a strong wind gybe can be fearsome, particularly if somebody lets happen by accident. If the mainsheet blocks fail you could seriously injure (or worse) crew members, break the boom or even take the mast out.

Clearly we all use gybe preventers and try to prevent accidental gybes. But if you do the miles it will happen eventually.

And the optimum system will depend on whether cockpit/transom mounted, like the diagram, or ahead of the cockpit, like the photograph.

Need to design the sheeting system fully before investing in expensive pulleys. We have a track ahead of the hatch, with mainsheet led back to helm, using all Ronstan blocks, which is ideal for us - but not the cheapest.

Then once designed and satisfied (possibly using a mock-up with thin rope and dinghy pulleys), be prepared to invest in quality blocks for this application. The forces after a strong wind gybe can be fearsome, particularly if somebody lets happen by accident. If the mainsheet blocks fail you could seriously injure (or worse) crew members, break the boom or even take the mast out.

Clearly we all use gybe preventers and try to prevent accidental gybes. But if you do the miles it will happen eventually.

Moodysailor

Well-Known Member

When I think about the idea of people making their own blocks, I am imagining the threads a few years later explaining how they had a failure at the most unfortunate moment that meant the boat couldn't be used/put lives in danger/caused damage (delete as appropriate).

15mm dia implies high loads, it's up the OP but I can't see that messing around trying to handcraft something for these loads on this application is a worthy cause.

FWIW when I needed to change the mainsheet blocks on our previous boat (16mm line) I downsized the line to dyneema and bought cheaper blocks. The line was re-purposed as a dockline which we needed anyway so it wasn't a waste.

15mm dia implies high loads, it's up the OP but I can't see that messing around trying to handcraft something for these loads on this application is a worthy cause.

FWIW when I needed to change the mainsheet blocks on our previous boat (16mm line) I downsized the line to dyneema and bought cheaper blocks. The line was re-purposed as a dockline which we needed anyway so it wasn't a waste.

anoccasionalyachtsman

Well-Known Member

These two mainsheets are very different.

Assuming the blocks in the phot don't slide on the white/blue rope, this system won't provide much leach tension as soon as the boom is off the centre line.

It's a fine system, I have iessentially the same on a dinghy, but I have a 16:1 vang bending a carbon boom to do the leach tension.

The system in the sketch, if you move the boom off centre, you have 2 strands of the main mostly pulling down and 2 pulling to windward and down.

Again it's a fine system, great if you don't have a strong enough boom for the kicker to do all the leach tension up wind, and your rig is designed for the boom not to be so close to the centreline.

I don't think you'll find any substantial difference between the leach tension vs. boom in/out angle on either system when their sheets are eased. As you say, massive vang tension would be needed.

A coachroof traveller is possibly the most pragmatic solution for a cruising boat, but two separate mainsheets deployed at similar angles to those pictures can work surprisingly well once you have your head around it. The leeward one does the leach and the wward acts like a traveller. Not as good as a wide traveller/track, but not at all bad.

AngusMcDoon

Well-Known Member

A single plain Barton block for 14mm rope is £27. A double £52, and a triple £62. There's a distributor in Oz. 14mm braid on braid polyester has a typical breaking strength of 4500kg. Bigger than that is not needed.