viva

Well-Known Member

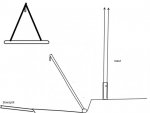

I want to lower and raise the 7.5m wooden mast on my 25ft gaff cutter. The wooden mast is held in a tabernacle on the coach roof. I am thinking of getting made an A frame made up from two scaffold poles(or similar) flattened and bolted together at the top which would also include a block. The base would be a round 2m wooden post of about 20cm diameter. The 2 scaffold poles would fit into round holes at the ends of the wooden base pole which would be placed and secured on the fore deck in front of the coach roof, such that the base pole can rotate as the mast is lowered.

My questions are

1 Ideally how long would the scaffold poles need to be.

2. What is the minimum length of the poles?

2. Would it work OK?

Many thanks to all responders

My questions are

1 Ideally how long would the scaffold poles need to be.

2. What is the minimum length of the poles?

2. Would it work OK?

Many thanks to all responders