AlexLbk

Active Member

Thank you - it's all I needed to know. The board is coming from Spain and I'm away for at least a week, so this will get done once I come back.Hello, no, the resistors must be removed.

This video gives a good summary of the test procedure:

In my experience if they have failed you will get a definite short on one of the readings.

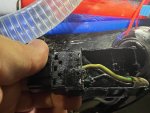

That still leaves a question of why the whole thing blew up. Assuming IGBTs are bad I will test the cooling circuit and see if the flow is sufficient. It was really hot that day - over 100F, the engine room was over 110 according to my data loggers.