dankilb

Well-Known Member

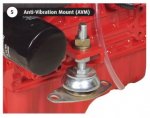

Just received four smart new engine mounts from the helpful folks at AV Industrial (who I think manufacture themselves and advised on the right model for our Beta 50):

Question is, what do I stud them with (M16)? Is regular (mild) threaded rod okay? Do I need HT/8.8? And I'm assuming (hoping?!) stainless not required/worth it?

TIA

Question is, what do I stud them with (M16)? Is regular (mild) threaded rod okay? Do I need HT/8.8? And I'm assuming (hoping?!) stainless not required/worth it?

TIA