weliwarmer

New Member

Hey,

I'm replacing my 50-year-old marine diesel with an inboard electric motor and need some advice with the thrust bearing please.

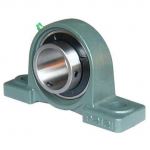

My design is based on a couple of other electric installations that I've see, including this one:

My propeller shaft will come through the cutlass and onto a bearing - that was not a problem with the diesel because it took the thrust but with the electric motor now driving the shaft via a belt, the shaft moves back and forth with the force from the prop. I don't want to have the cutlass bearing take the force or the current bearing, which is not suitable for axial loads.

I don't want to go the aquadrive way and pay £££ for this part so....

I would think that the normal ballbearing bearings would not be suitable for the axial load but that's only me guessing. Anyone know different?

The thrust should be about 100kg) - would the grub screws that seem to be fitted to most bearings/collars be enough or would the bearings/collars need welding to the shaft?

Thanks, Tim

I'm replacing my 50-year-old marine diesel with an inboard electric motor and need some advice with the thrust bearing please.

My design is based on a couple of other electric installations that I've see, including this one:

My propeller shaft will come through the cutlass and onto a bearing - that was not a problem with the diesel because it took the thrust but with the electric motor now driving the shaft via a belt, the shaft moves back and forth with the force from the prop. I don't want to have the cutlass bearing take the force or the current bearing, which is not suitable for axial loads.

I don't want to go the aquadrive way and pay £££ for this part so....

I would think that the normal ballbearing bearings would not be suitable for the axial load but that's only me guessing. Anyone know different?

The thrust should be about 100kg) - would the grub screws that seem to be fitted to most bearings/collars be enough or would the bearings/collars need welding to the shaft?

Thanks, Tim