simonfraser

Well-Known Member

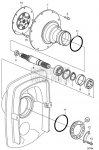

i am no mechanic, this is the bearing that the shaft forward of the U joint fits into ?

sits in the transom shield ?

can this be tested as it may be worn and causing vibration ?

and is it removable from the stern ?

p.s. the gear shift cable on a KAD44 EDC goes straight from the KAD to the DPE and thus is relatively simple to replace ?

tnx

sits in the transom shield ?

can this be tested as it may be worn and causing vibration ?

and is it removable from the stern ?

p.s. the gear shift cable on a KAD44 EDC goes straight from the KAD to the DPE and thus is relatively simple to replace ?

tnx