LittleSister

Well-Known Member

FURTHER UPDATE:

I found that the Bukh Workshop manual does have info on removal/replacement of the injection pump (I'd somehow missed it before), albeit in Bukh's usual somewhat opaque translation. It convinced me the job was beyond what I should take on just now.

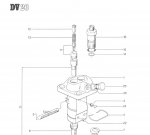

I did find the following useful explanation and drawings of the Bosch VE pump, and both how it works and which bit is which is now much clearer to me. http://stuff.is-a-geek.net/OnlineDocs/Vehicles/vepump.html

Fox's and several others didn't want to do the job of taking off and replacing the pump - too booked up, most of them say. I have now, though, found someone called Travis(?) who can. (I think he's based at Ipswich Haven.)

I found that the Bukh Workshop manual does have info on removal/replacement of the injection pump (I'd somehow missed it before), albeit in Bukh's usual somewhat opaque translation. It convinced me the job was beyond what I should take on just now.

I did find the following useful explanation and drawings of the Bosch VE pump, and both how it works and which bit is which is now much clearer to me. http://stuff.is-a-geek.net/OnlineDocs/Vehicles/vepump.html

Fox's and several others didn't want to do the job of taking off and replacing the pump - too booked up, most of them say. I have now, though, found someone called Travis(?) who can. (I think he's based at Ipswich Haven.)