oak123

New Member

Ok, so to be precise, I don't own a yacht so I'm mainly going here because I've been reading about similar setups with the Racor fuel/water separator with the spin-on-bowl setup on your diesel engines. What I have is actually a loader that I upgraded the engine to a Kubota V1505 (4 cylinder diesel). Its commonly used in generators, and Kubota tractors but I have it installed in a tractor (custom). So technically I have a yacht, but it only runs on land.  (Now if you're buying this part of the story, read on:encouragement

(Now if you're buying this part of the story, read on:encouragement .

.

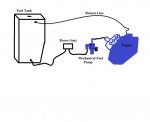

So, I purchased and installed the Racor R12T, 10 micron,15 GPH, 4 port setup (but only using 2 ports). I attached a schematic of what my fuel system setup looks like. Image also shows the input output ports. So, initially I had some minor problems with the barbs, O-ring on bowl, and vent plug o-ring leaking on the filter. I applied thread sealant on barbs, got a bigger o-ring for the bowl (Napa), and replaced the vent plug o-ring on the vent. At this point I lost all my faith in Racor, so I pressure tested the filter in a bucket of water to see if there were any more leaks. Everything checked out so I reassembled everything and ran the engine. Saw some bubbles coming up through the return line and decided that I was probably missing something. I installed a clear line from the mechanic lever pump to the injection high pressure pump to see if there was an air bubbles coming from the suction side. A small stream of bubbles were traveling from the mechanical pump. I thought it was a bad diaphragm so I replaced the mechanical pump with a new one. Same problem persists. (this is a fairly brand new engine with about less than 100 hours).

Diagnosing the mystery air problem further, here is what I came up with:

Running engine at idle: I inspected the 1/4" fuel line going from the Racor filter to the mechanical pump. No air bubbles. Then I checked the clear tube going from the mechanical pump to the injector pump, small stream of air bubbles.

Running engine at higher RPM's: No air bubbles after Racor filter, also, no air bubbles after the mechanical pump.

So to conclude, it seems like the air is being formed/sucked only at lower RPM's. I thought that maybe turbulence was being formed at the mouth of the metal tubes coming from the mechanical pump, but this wouldn't make any sense if the RPM's change. Another problem with this engine is that it vibrates a lot more at lower RPM's. Thus, it seems like when I find the "sweet-spot" at higher RPM's, I also lose the air bubbles. There is also a constant supply of air bubbles in the return line traveling to the tank, this maybe due to the way I have my tank designed. Any thoughts, input, suggestions will be appreciated because at this point I'm at a complete loss...

So, I purchased and installed the Racor R12T, 10 micron,15 GPH, 4 port setup (but only using 2 ports). I attached a schematic of what my fuel system setup looks like. Image also shows the input output ports. So, initially I had some minor problems with the barbs, O-ring on bowl, and vent plug o-ring leaking on the filter. I applied thread sealant on barbs, got a bigger o-ring for the bowl (Napa), and replaced the vent plug o-ring on the vent. At this point I lost all my faith in Racor, so I pressure tested the filter in a bucket of water to see if there were any more leaks. Everything checked out so I reassembled everything and ran the engine. Saw some bubbles coming up through the return line and decided that I was probably missing something. I installed a clear line from the mechanic lever pump to the injection high pressure pump to see if there was an air bubbles coming from the suction side. A small stream of bubbles were traveling from the mechanical pump. I thought it was a bad diaphragm so I replaced the mechanical pump with a new one. Same problem persists. (this is a fairly brand new engine with about less than 100 hours).

Diagnosing the mystery air problem further, here is what I came up with:

Running engine at idle: I inspected the 1/4" fuel line going from the Racor filter to the mechanical pump. No air bubbles. Then I checked the clear tube going from the mechanical pump to the injector pump, small stream of air bubbles.

Running engine at higher RPM's: No air bubbles after Racor filter, also, no air bubbles after the mechanical pump.

So to conclude, it seems like the air is being formed/sucked only at lower RPM's. I thought that maybe turbulence was being formed at the mouth of the metal tubes coming from the mechanical pump, but this wouldn't make any sense if the RPM's change. Another problem with this engine is that it vibrates a lot more at lower RPM's. Thus, it seems like when I find the "sweet-spot" at higher RPM's, I also lose the air bubbles. There is also a constant supply of air bubbles in the return line traveling to the tank, this maybe due to the way I have my tank designed. Any thoughts, input, suggestions will be appreciated because at this point I'm at a complete loss...