Nicman

New Member

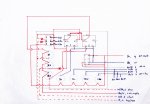

I have a Betamarine engine and when I press the heat button for a few seconds the engine panel shows a few lights and the fuel level gauge works etc. But as soon as I start the engine, the panel goes totally dead and no lights and all gauges go to zero. However the engine keeps running with a dead panel. Any experts out there with a simple solution? Please help...!