PaulRainbow

Well-Known Member

Paul, or anyone else that may help.

Wago make lots of different connectors Vas, i'm sure there's something that would fit the bill ;

https://www.wago.com/gb/

Paul, or anyone else that may help.

Wago make lots of different connectors Vas, i'm sure there's something that would fit the bill ;

https://www.wago.com/gb/

All I can say is BE CAREFUL.

I've tested several, and many gave the impression of a good connection, but were in fact very weak. Only use brand names. 3M is very good. Some of the Amazon shite was worse than just twisting and taping. Really. And it is hard to tel the difference unless you make some test connections, pull test them and then cut them open.

Whatever you use, pull-test a few to make sure. They should be strong enough to break the wire or they really should not go on a boat.

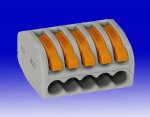

For small NMEA 0183 cables i use two methods, solder and heat shrink is obviously one way. Another good method is to use Wago connectors https://www.screwfix.com/p/wago-2-way-lever-connector-221-series-32a-pack-of-100/8421r

These will hold fine stranded cable down to 0.14mm and up to 4mm. I often stick the connectors in place with a spot of quick drying epoxy. For instance, if i'm fitting a chart plotter in a pod at the helm i run the cabling through the stainless tubing and epoxy some Wago connectors in the pod for the power cable and any NMEA cables. Just slip the wires in, close the lever and you're done. Makes it nice and easy to make future changes, as the are reusable, and a couple of small cable ties around all of the wires ensure everything is held firmly in place.

I too have used cheap Amazon solder-connectors and found them poor. Sometimes the solder does not fully melt and join the wires, and if you use enough heat to definitely get a sound soldered connection the external plastic starts to burn and I worry if it is still waterproof. If I need a similar connection again I'll try and get better quality ones.

For waterproof joins, instead of the solder type ones i use glue lined, heat shrink crimp connectors. Crimp well with appropriate crimping tool and then you don't have to heat too much to shrink and seal.

Thise wago connectors look ideal for connections in the cabin. Never seen them before, either! now just have to see if I can find them, here in NZ....

Is there a link for the glue lined, heat shrink crimp connectors?

These wago connectors look ideal for connections in the cabin. Never seen them before, either! now just have to see if I can find them, here in NZ....

Vas If you have space for a length of top hat DIN rail then these are excellent when used also with boot lace ferrules on the cable ends ...Paul, or anyone else that may help,

is there any such contraption that one could mount on an electronics box (with lots of arduino kit inside) that would enable easy attachment of cables coming from sensors all around?

I mean I've used M20 or whatever size that is 5-6-8 connectors but jamming and soldering even 6 wires in that and getting it all looking decent is no mean job!

It would be easier if I could have something like that with numbered single lever wire inputs that would on the other side of the enclosure connect wires to the PCB.

So not two or three wires joint together , but a series of wires "terminating" on these levers and driving signals inside the box.

sorry not a v. good description...

cheers

V.

Paul, or anyone else that may help,

is there any such contraption that one could mount on an electronics box (with lots of arduino kit inside) that would enable easy attachment of cables coming from sensors all around?

I mean I've used M20 or whatever size that is 5-6-8 connectors but jamming and soldering even 6 wires in that and getting it all looking decent is no mean job!

It would be easier if I could have something like that with numbered single lever wire inputs that would on the other side of the enclosure connect wires to the PCB.

So not two or three wires joint together , but a series of wires "terminating" on these levers and driving signals inside the box.

sorry not a v. good description...

cheers

V.

From Germany, common in the US in industry and elelctronics, not so much for DIY and hardware stores.

In a cabinet is one thing. On boat, corrosion resistants and watertight integrity often matters, even just from condensation. Unless I'm mistaken, the spring in WAGO connectors is ordinary spring steel and they can't be sealed.

The other problem is strain relief.

I've heard a lot about these. I've used them in industry, mostly in the lab, and they certainly are 3 steps above wire nuts. I want to here more about them on boats.