silvercreek

New member

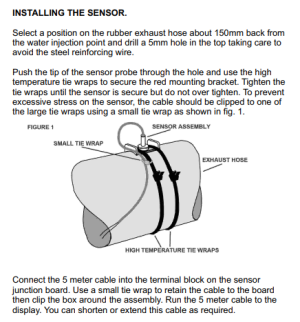

I would like to measure the exhaust gas temp just after the exhaust elbow where water is injected. This means I'll need to drill into the 90mm diameter heavy duty exhaust hose. Any tips for this to ensure a leak-free connection?

This is the sensor I'm planning to use: Exhaust Gas Sensor YDGS-01

This is the sensor I'm planning to use: Exhaust Gas Sensor YDGS-01