jdc

Well-Known Member

... but still confused as to the reason my anchor doesn't always come up the same way...

Me too! But the explanation may be just due to the sum of lots of small, random, twists. Very 'back of cigarette packet' stuff, but note that chain is made so that the inside diameter of the link's 'loop' is at least 1.5x the diameter of the wire itself (eg 8mm wire, 12mm inside link) see http://www.williamhackett.co.uk/en-...bulk_chain/grade_30_short_link_chain/p-107153.

This means that the potential energy minimum when chain is under tension is not V shaped but very U shaped, or even flat bottomed - a complicated way of saying that the chain can twist a bit on each link even when under tension, maybe by +/-10 degrees or so at a guess, and for this exercise let's assume these twists are uniformly distributed between -10 and +10 degrees, with a mean of zero.

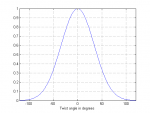

In the length between windlass and anchor there may be 30 links. Convolving the small random twists of the 30 links gives this distribution:

As you can see, there is some chance that the twist is greater than 90 degrees, whereupon the anchor will, irritatingly, flip over on the roller.

I'm not at all sure this is the explanation, and as I said the numbers are just initial guesses.