zoidberg

Well-Known Member

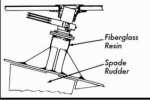

Thanks. I'll look at providing further support by means of a guide bearing as suggested by MikeGunn in #38. The firm who provided the featured spherical bearing, IGUS, should be able to provide me with a solution.

Dispensing with the original wide slot is a primary objective. It is a 'downflooding hazard', and breaches my First Principle - 'Keep the ocean on the outside'.

It is VIP to eliminate all possible sources of friction in the operation of any windvane gear, most especially in light airs. Concertina bellows in the transom would multiply line-friction and admit unwanted seawater to the inside.

The geometry of the 'lead' of the tiller controlling lines is important. The original arrangement would have the lines pulling the tiller UP as well as sideways, causing it to scrape on the upper arch of the slot i.e. friction The new arrangement has the tiller raised to the optimum height so that the lines come horizontally.

The tiller, restrained in that slot, traps the manual helmsman's legs in place if/when the rudder is forced fully over when going astern.

When picking up a mooring buoy, I like to stand on the cockpit seats to keep sight of the 'target' as it disappears below the bow. That involves a lifting tiller.

We're getting there....

Dispensing with the original wide slot is a primary objective. It is a 'downflooding hazard', and breaches my First Principle - 'Keep the ocean on the outside'.

It is VIP to eliminate all possible sources of friction in the operation of any windvane gear, most especially in light airs. Concertina bellows in the transom would multiply line-friction and admit unwanted seawater to the inside.

The geometry of the 'lead' of the tiller controlling lines is important. The original arrangement would have the lines pulling the tiller UP as well as sideways, causing it to scrape on the upper arch of the slot i.e. friction The new arrangement has the tiller raised to the optimum height so that the lines come horizontally.

The tiller, restrained in that slot, traps the manual helmsman's legs in place if/when the rudder is forced fully over when going astern.

When picking up a mooring buoy, I like to stand on the cockpit seats to keep sight of the 'target' as it disappears below the bow. That involves a lifting tiller.

We're getting there....